When we envision a battery, we typically picture a rigid and unyielding structure. However, in the realm of flexible electronics, where wearable health monitors are becoming increasingly popular, batteries must possess the ability to stretch and bend. A recent study published in ACS Energy Letters introduces a ground-breaking lithium-ion battery composed of entirely stretchable components, including an electrolyte layer capable of expanding by a staggering 5,000%. This innovative battery retains its charge storage capacity even after nearly 70 charge/discharge cycles. The demand for batteries that can conform to the contours of bendable and stretchable electronics is on the rise. While previous attempts at creating such batteries involved woven conductive fabric or rigid components folded into adaptive shapes, the key to a truly pliable battery lies in ensuring every component, from the electrodes to the electrolyte layer, possesses elastic properties.

Many existing prototypes of stretchy batteries exhibit moderate elasticity, complex assembly procedures, or limited energy storage capacity, particularly over prolonged use with repeated charging and discharging. The primary reasons for this diminished performance include a weak connection between the electrolyte layer and electrodes, as well as the instability of the liquid electrolyte, which can shift within the battery when subjected to changes in shape. In an effort to address these challenges, Wen-Yong Lai and his team sought to embed the electrolyte within a polymer layer sandwiched between two flexible electrode films, thereby creating a solid, stretchable battery.

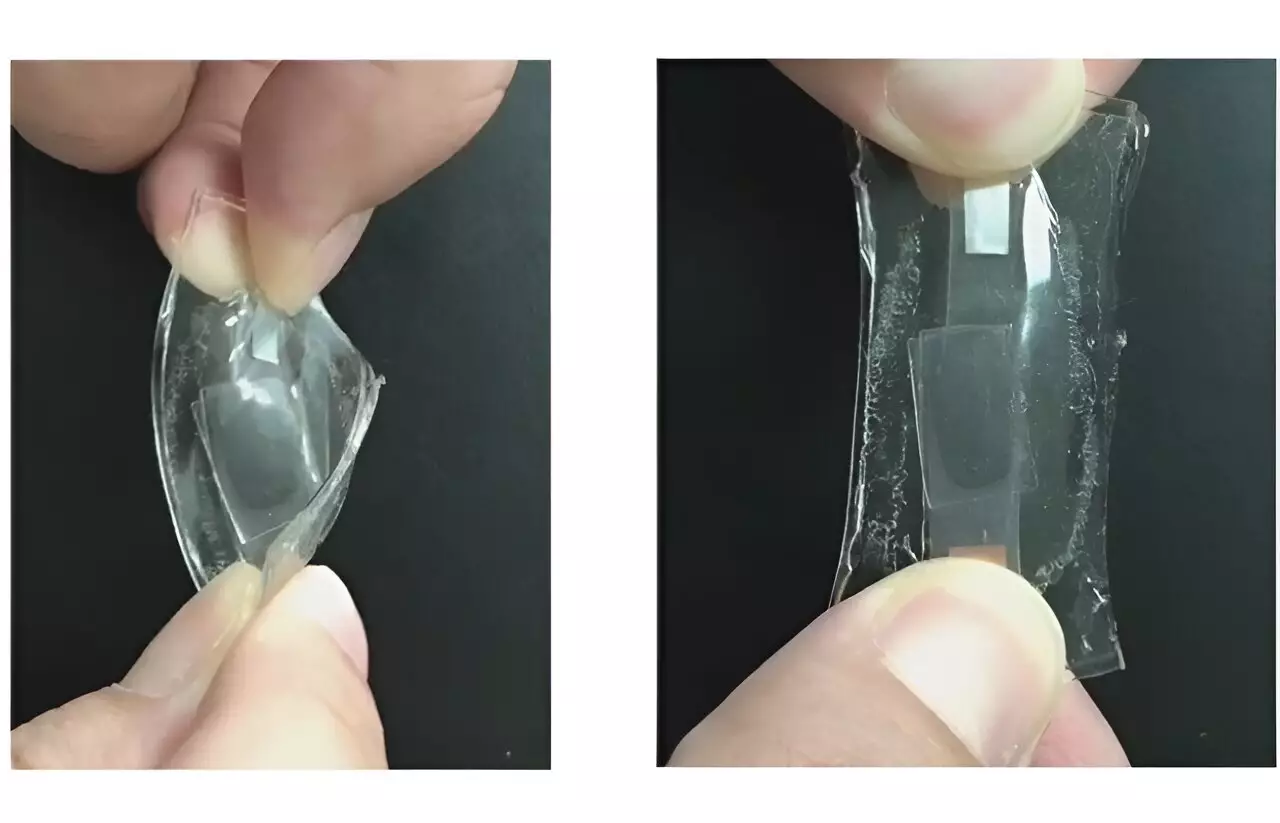

To construct the electrodes for the fully elastic battery, the researchers first applied a thin film of conductive paste containing silver nanowires, carbon black, and lithium-based cathode or anode materials onto a plate. Subsequently, a layer of polydimethylsiloxane, a flexible material commonly employed in contact lenses, was added on top of the paste. The team then introduced a lithium salt, a highly conductive liquid, and the necessary elements to produce a stretchy polymer directly onto this film. Upon activation by light, these components amalgamated to form a solid, rubbery layer capable of stretching up to 5,000% of its original length while facilitating the transportation of lithium ions. To complete the structure, another electrode film was placed on top of the stack, and the entire device was encased in a protective coating.

In comparison to a similar device incorporating a traditional liquid electrolyte, the newly developed solid stretchy battery exhibited approximately six times higher average charge capacity at a fast-charging rate. Moreover, the solid battery demonstrated a more consistent capacity throughout 67 charging and discharging cycles. Notably, in other prototypes featuring solid electrodes, the polymer electrolyte maintained stable operation over 1,000 cycles, with capacity decreasing by a mere 1% within the initial 30 cycles, in stark contrast to the 16% decline observed in batteries utilizing liquid electrolytes.

Though there are still enhancements to be made, the groundbreaking approach to creating fully stretchable, solid batteries represents a significant leap forward in the realm of wearable and implantable devices that must flex and move in harmony with the human body. By overcoming the challenges of elasticity and stability, this novel technology paves the way for a new era of flexible electronics that seamlessly integrate into our daily lives. The potential applications of stretchable batteries extend far beyond wearable health monitors, encompassing a wide array of innovative devices that will redefine the boundaries of modern technology.

Leave a Reply