The push for renewable energy solutions has led to the exploration of various technologies to generate electricity, including photovoltaics, wind turbines, and hydro-power generators. In addition to these, the conversion of excess or waste heat into electricity through thermoelectric power generation has gained attention as a potential solution to mitigate climate change. This method relies on materials with valuable thermoelectric properties that can generate electricity when exposed to temperature differentials.

Recent research by engineers and scientists from Pohang University of Science and Technology, the George Washington University, and other institutes has introduced a new strategy for designing thermoelectric materials based on copper selenide (Cu2Se). This innovative approach enables the creation of promising materials for high-power generation using techniques that are easier to reproduce on a large scale.

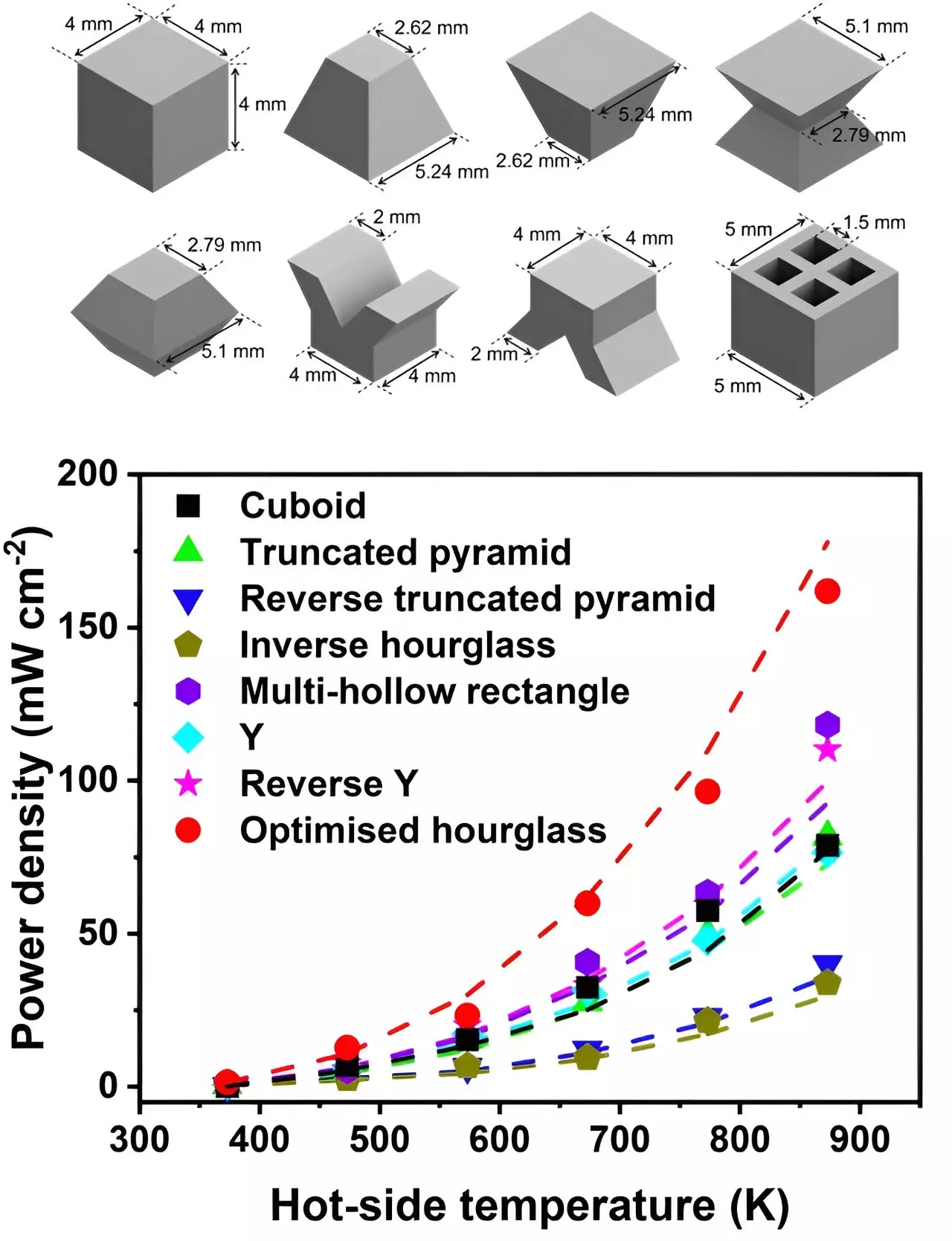

Traditional thermoelectric devices typically consist of p- and n-type semiconductor legs in a thermocouple configuration. The design of these legs plays a critical role in optimizing thermal and electrical resistances to maximize power generation. By exploring non-cuboid three-dimensional (3D) geometries for the semiconductor legs, researchers aim to enhance device performance beyond what can be achieved with cuboid legs.

The research team led by Prof. Saniya LeBlanc at the George Washington University conducted a series of simulations to explore the impact of semiconductor leg shape on thermoelectric performance. Subsequently, the team used 3D printing techniques to fabricate non-cuboid geometries for the semiconductor legs, allowing for experimental assessment of their performance. The study focused on Cu2Se as a model material due to its high efficiency at high temperatures.

Experimental results revealed that legs with an hourglass-shaped geometry exhibited the highest power generation output and efficiency. The controlled liquid-phase sintering technique employed by the researchers led to the formation of defects in the Cu2Se material, reducing thermal conductivity and enhancing ZT values up to 2.0. These findings emphasize the significant impact of 3D geometry on the electrical current generated by thermoelectric materials.

Future Applications and Research

The study by Son and his colleagues demonstrates the potential of applying non-cuboid geometries to enhance the performance of thermoelectric power generators. While Cu2Se was used as a model material in this research, the new design strategy could be applied to other types of thermoelectric materials in the future. Researchers aim to further explore the application of non-cuboid geometries in segmented devices and Peltier cooling modules to improve overall performance.

The study sheds light on the importance of 3D geometry in optimizing the power generation capabilities of thermoelectric materials. By leveraging innovative design strategies and fabrication techniques, researchers have the potential to enhance the efficiency and output of thermoelectric power generators. This opens up new possibilities for sustainable energy generation and paves the way for further advancements in the field of renewable energy technologies.

Leave a Reply