The use of cellulose nanofibrils as an additive in 3D-printed concrete technology has the potential to revolutionize the construction industry. Research led by engineers at the University of Virginia School of Engineering and Applied Science suggests that incorporating cellulose nanofibrils into printable materials could enhance both the printability and mechanical properties of 3D-printed structures. This groundbreaking research could pave the way for more sustainable and durable construction practices in the near future.

3D-printed concrete structures offer a wide range of benefits, including quick and precise construction, the potential use of recycled materials, reduced labor costs, and minimized waste. In addition, the flexibility of 3D printing technology allows for the creation of intricate designs that may be challenging to achieve using traditional construction methods. However, the current limitations of printable materials in terms of sustainability and durability have remained a significant challenge in the industry.

Cellulose nanofibrils, derived from wood pulp, are renewable and have a low environmental impact. These plant-based materials show promise as additives to enhance the flow properties and mechanical strength of 3D-printed concrete composites. The use of cellulose nanofibrils, also known as CNF, in the construction industry has the potential to improve the overall performance of 3D-printed structures.

Research Findings

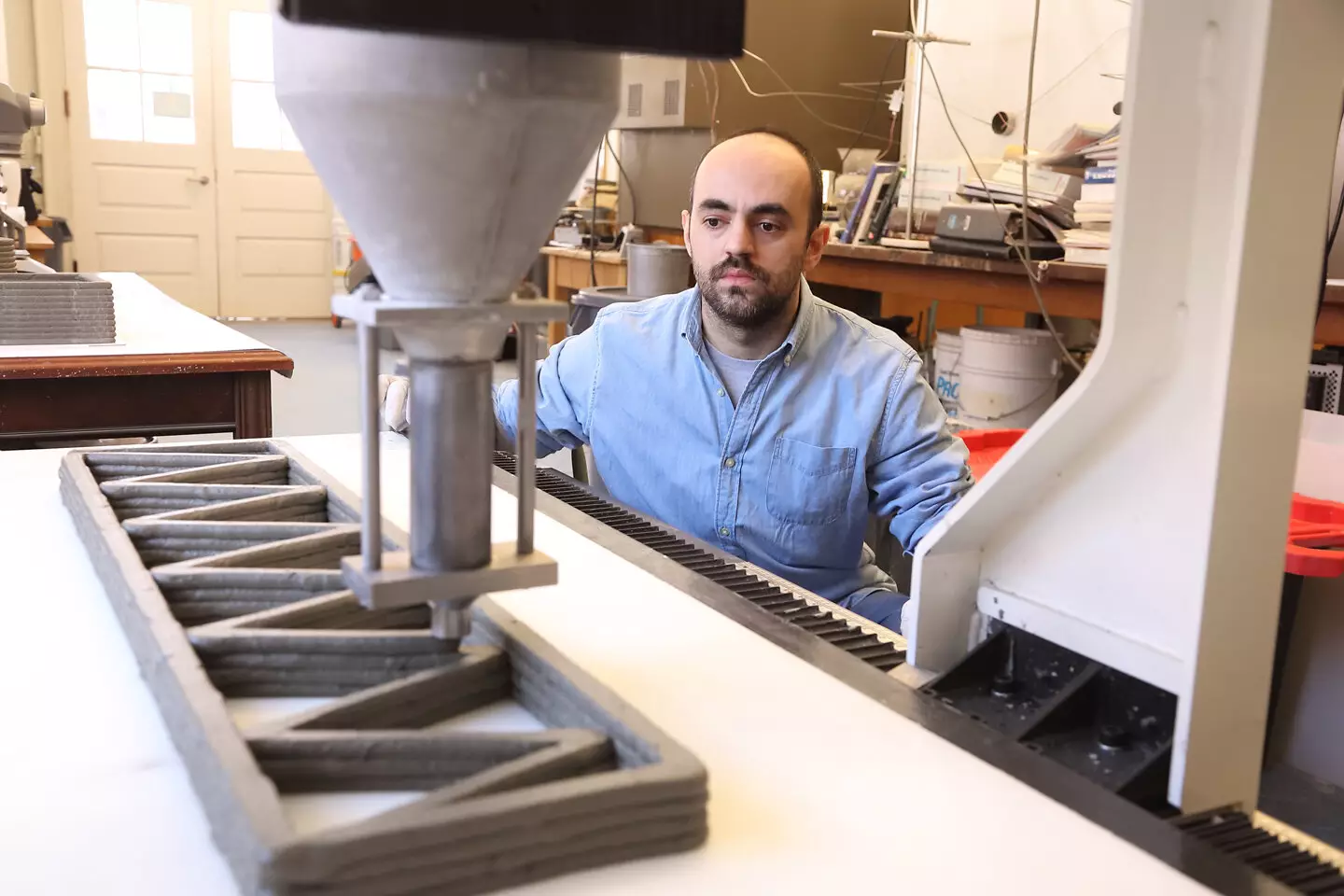

The research conducted by the UVA-led team, under the leadership of Professor Osman E. Ozbulut and Ph.D. alumnus Ugur Kilic, demonstrated the significant benefits of incorporating cellulose nanofibrils into 3D-printed concrete. By adding as little as 0.3% CNF, the flow performance of the printable material was enhanced, leading to better material bonding and structural integrity in the hardened samples. The CNF-enhanced 3D-printed components also exhibited improved resistance to pulling, bending, and compression, indicating a potential increase in overall durability.

The use of cellulose nanofibrils as an additive in 3D-printed concrete technology shows great promise for improving the sustainability, durability, and overall performance of construction practices. The findings of this research suggest that incorporating CNF into printable materials could lead to more resilient and eco-friendly construction practices in the future. Further exploration and development of cellulose nanofibrils in 3D printing technology could revolutionize the construction industry and pave the way for a more sustainable future.

Leave a Reply