The world of particle acceleration is undergoing a revolution with the development of laser-plasma accelerators. These compact facilities are able to accelerate electron bunches efficiently, enabling the creation of X-ray lasers that can fit in the basement of a university institute. Unlike conventional facilities that can span kilometers in length, laser-plasma accelerators take up significantly less space while delivering impressive results.

While the potential of laser-plasma accelerators is vast, there are challenges that need to be addressed. In order to produce UV or X-ray light, the electron bunches generated by these accelerators must be tightly bundled and exhibit specific properties. However, accurately measuring these bunches has proven to be a difficult task until now. A team at Helmholtz-Zentrum Dresden-Rossendorf (HZDR) has developed a novel measuring method that aims to propel the advancement of laser-plasma acceleration technology.

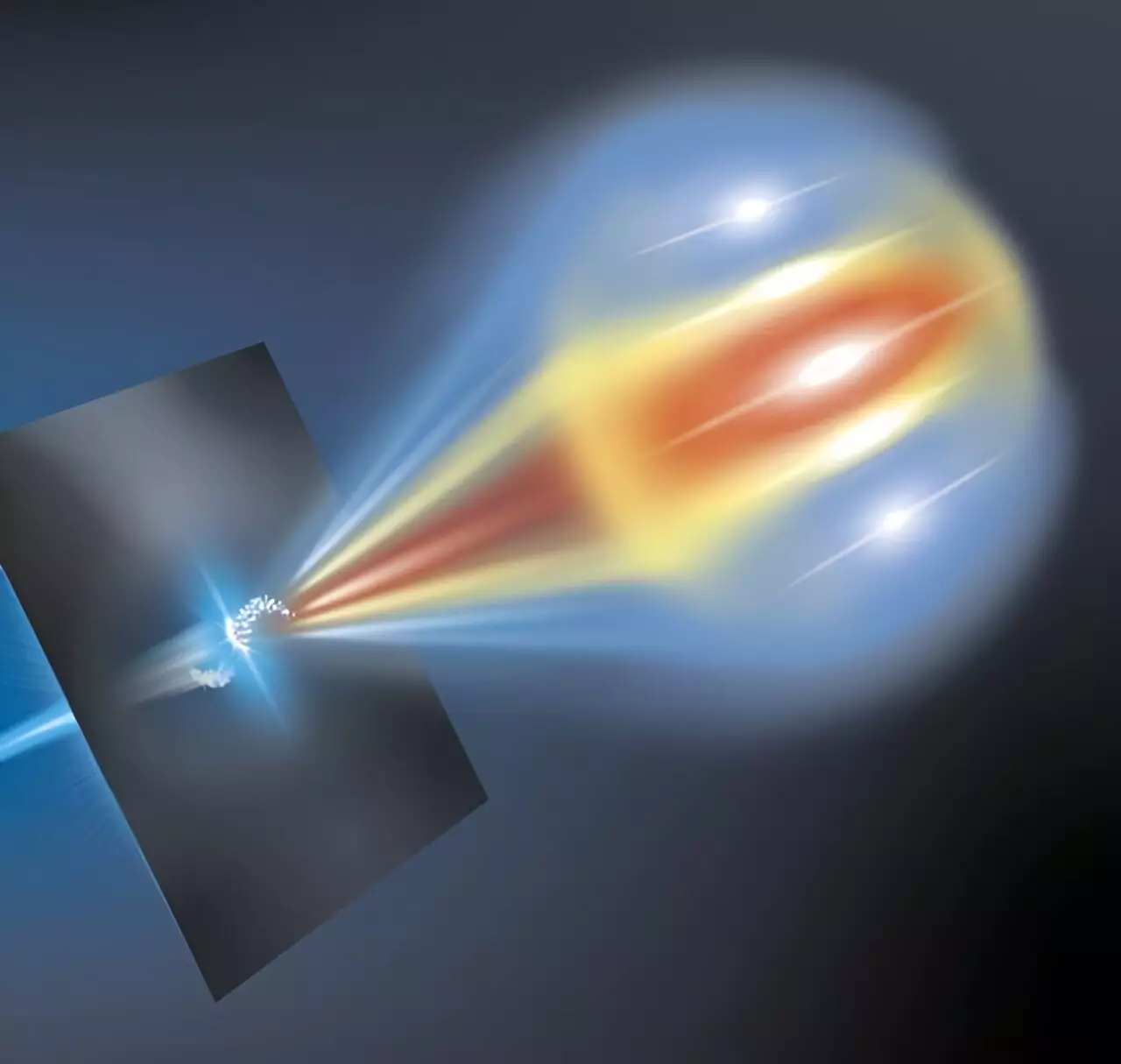

In laser-plasma acceleration, a laser is used to shoot intense light pulses into a gas, creating a plasma consisting of electrons and ions. As the laser pulse interacts with the plasma, a positively charged “bubble” is formed behind it. By injecting electrons into this bubble, the electric field can accelerate them forward rapidly. This entire process takes only a few centimeters, in stark contrast to conventional accelerators that span dozens or hundreds of meters.

One of the most exciting applications of laser-plasma accelerators is the free electron laser (FEL). In FEL setups, electron bunches travel through an undulator at nearly the speed of light, emitting powerful X-ray or UV flashes. These flashes can be used to observe ultra-fast processes such as chemical reactions that occur in quadrillionths of a second. Facilities like the European XFEL in Hamburg have demonstrated the potential of FELs but are limited by their size and cost.

Recent successes in the field have shown that it is possible to construct FELs based on laser-plasma accelerators. Research groups in Shanghai, Frascati, and at HZDR have made significant progress in this area. By improving the quality and stability of accelerated electron bunches and developing new diagnostic methods, researchers are paving the way for more precise control over the acceleration process.

A breakthrough in laser-plasma acceleration research comes from the development of a new measuring procedure at HZDR. Dr. Maxwell LaBerge, a postdoc in the team led by Dr. Arie Irman, has devised a method to analyze extremely short electron bunches measuring only a few micrometers. This technique, known as Coherent Optical Transition Radiation (COTR), involves shooting electron bunches onto a thin metal foil and analyzing the emitted signal.

Through the use of this new measuring method, researchers have gained valuable insights into different methods of injecting electrons into the plasma bubble. By controlling the form and structure of electron bunches more precisely, scientists are able to enhance the brightness and stability of the light produced in an FEL. This level of control opens up new possibilities for the future of particle acceleration technology.

Laser-plasma accelerators represent a significant advancement in the field of particle acceleration. With their compact size, efficiency, and potential for groundbreaking research, these accelerators are poised to revolutionize the way we study and understand the fundamental building blocks of the universe. By overcoming challenges, pushing the boundaries of innovation, and developing novel techniques, researchers are laying the foundation for a new era of particle physics.

Leave a Reply