In today’s technologically driven world, the increasing complexity of integrated microelectronic devices poses significant challenges in repairability and recycling. As these devices become more compact and sophisticated, traditional repair methods are often rendered ineffective. This situation not only leads to a surge in electronic waste but also contradicts the principles of a circular economy that advocates for sustainable resource utilization and minimal waste production. The urgency to address these challenges has spurred researchers to explore innovative solutions that facilitate repair and recycling, thereby aligning with environmental sustainability objectives.

One promising approach to enhance the repairability of modern electronics is the development of debondable adhesives. Unlike conventional adhesives, which bond surfaces permanently, debondable adhesives allow for the controlled deactivation of adhesion properties. This capability is crucial for the intelligent dismantling of devices, making it easier to repair or recycle individual components without causing damage to the surrounding materials. Researchers have been particularly intrigued by the natural adhesion mechanisms found in marine organisms, such as mussels, which have inspired the creation of novel adhesives with enhanced functionality and sustainability.

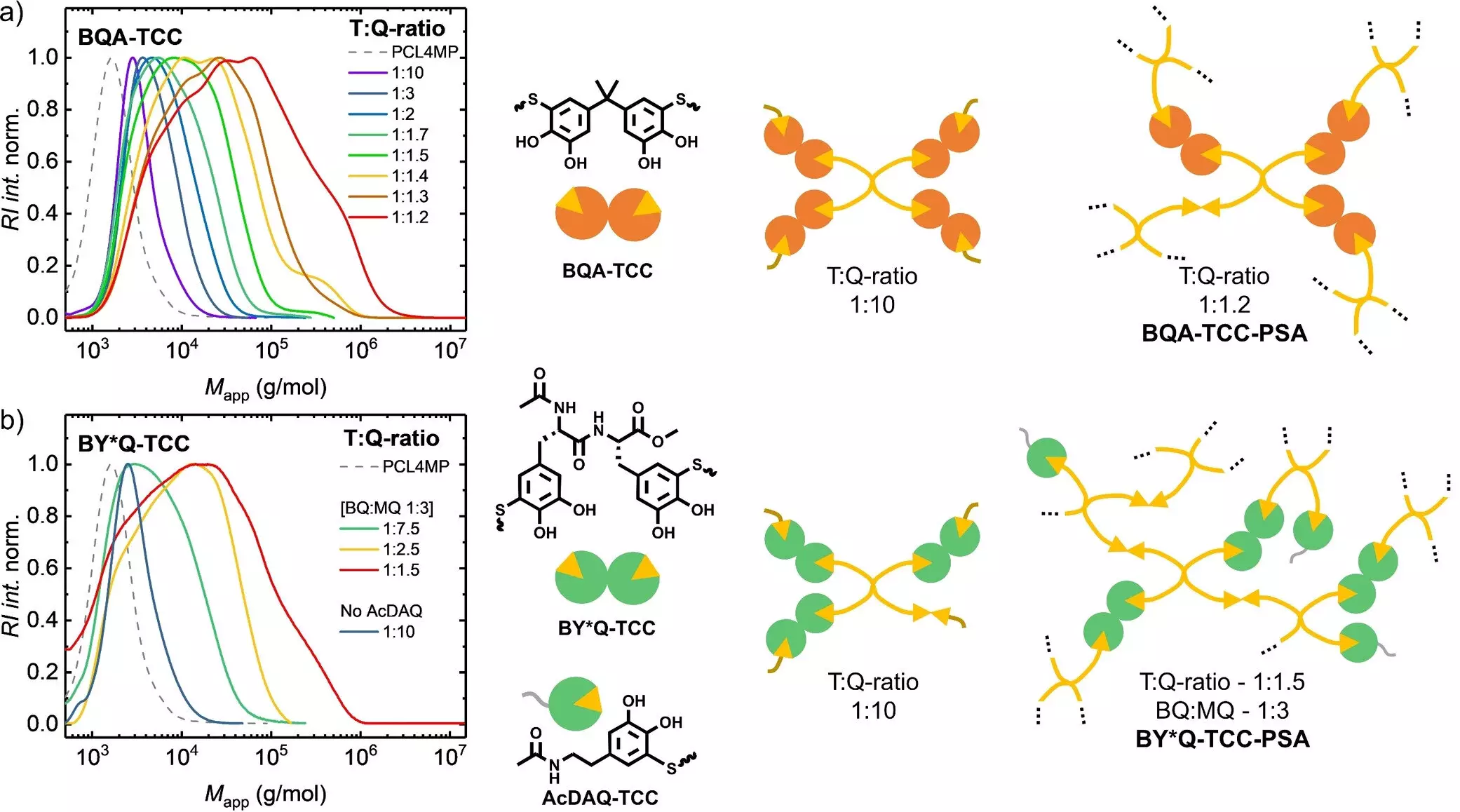

A recent study published in the renowned journal Angewandte Chemie highlights a groundbreaking approach that harnesses these natural principles. Researchers from multidisciplinary institutions, including Humboldt University Berlin and the Fraunhofer Institute for Applied Polymer Research, focused on developing adhesives derived from thiol-catechol polyaddition. This method employs polymers characterized by a combination of thiol and catechol groups, harnessing their inherent adhesive properties.

The crux of this innovation lies in the unique response of catechol groups when subjected to oxidation. Under normal conditions, these groups exhibit strong adhesive properties, but upon oxidation to form quinones, the adhesion significantly weakens. This selective responsiveness offers a novel strategy for controlling adhesion on command, making it particularly valuable for applications where temporary adhesion is essential.

The research team undertook a comparative analysis of biobased adhesive precursors, specifically those mimicking the natural composition found in mussels, against their fossil fuel-derived counterparts. Both adhesive types displayed robust adhesion and shear strength, functional even in aquatic environments while remaining resistant to mild oxidizing agents. However, the distinguishing factor emerged during the exposure to stronger oxidizing agents like sodium periodate. While the fossil-based adhesive became more hydrophobic along with diminished adhesion, the biobased variant managed to retain its hydrophilic properties.

Kannan Balasubramanian, a lead researcher, noted the remarkable efficiency of the biobased adhesive’s deactivation mechanism. Compared to the fossil-based adhesive’s 60% reduction in adhesive strength, the biobased adhesive demonstrated an astounding 99% decrease, showcasing its potential as a superior alternative in adhesive technology.

The promising outcomes of this research not only pave the way for improved adhesive technologies but also highlight the need for sustainable practices in consumer electronics. The team is next focusing on the integration of electrochemical oxidation techniques to achieve even more efficient adhesive deactivation methods. This evolution could revolutionize practices in repairing consumer electronics, such as smartphones, where temporary adhesion can streamline maintenance processes and reduce waste.

Furthermore, this innovative research signifies a paradigm shift in materials science, emphasizing the necessity of biomimicry and sustainable resource management in crafting future technologies. By bridging the gap between laboratory research and real-world applications, the findings could transform our approach to electronic device lifecycle management, ultimately contributing to a more sustainable future.

As the pressure to mitigate electronic waste grows, the exploration of advanced materials like the debondable adhesives outlined in the recent research becomes increasingly important. Through a marriage of natural inspiration and cutting-edge science, we stand on the brink of a materials revolution with the potential to redefine how we interact with electronic devices. The transition toward sustainable repairability not only promises to reduce waste but also embodies a forward-thinking approach essential in the 21st century.

Leave a Reply