As the world grapples with increasing amounts of electronic waste (e-waste), scientists are continuously searching for innovative methods to manage this environmental challenge. A groundbreaking study led by James Tour at Rice University has introduced a remarkable technique aimed at recycling critical metals from e-waste, which not only enhances efficiency but also minimizes the ecological footprint of metal retrieval processes. This advancement aligns with the urgent need for sustainable practices that mitigate the adverse effects of mining, including habitat destruction, pollution, and greenhouse gas emissions.

Traditional recycling approaches, such as hydrometallurgy and pyrometallurgy, have long been the backbone of metal recovery. However, these methods are often fraught with challenges, including high energy consumption, harmful waste production, and reliance on corrosive acids. The consequences of these practices are alarming, as they lead to significant environmental degradation while failing to meet the escalating demand for critical materials like gallium, indium, and tantalum. As metal shortages loom, the urgency for a more effective solution becomes even more pressing.

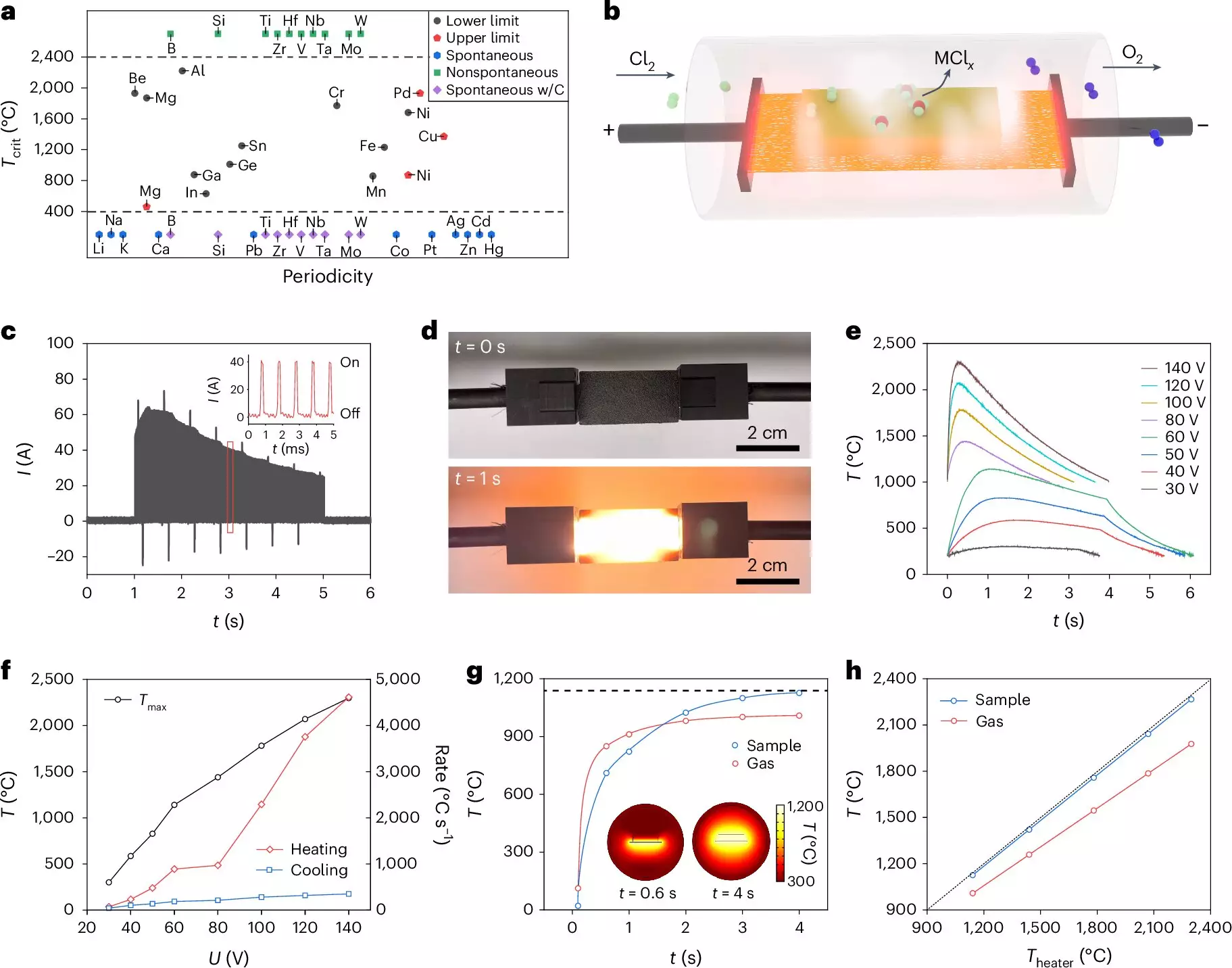

The Rice University research team’s innovative approach utilizes a process known as flash Joule heating (FJH), which allows for rapid heating of materials through electric current. This technique stands out as it facilitates efficient metal separation while controlling the temperature with precision. In their study published in *Nature Chemical Engineering*, the team successfully applied FJH methods, namely chlorination and carbochlorination, to recover valuable metals with remarkable efficiency. This new process transforms e-waste into a resource, shifting the paradigm from waste disposal to resource recovery.

Significant Advances in Purity and Yield

The data from the researchers is particularly promising. By optimizing reaction conditions, they achieved a metal recovery purity exceeding 95% and a yield surpassing 85%. This kind of efficiency not only proves the viability of the new method but also holds potential for broader applications, including the extraction of lithium and rare Earth elements. The ability to recover these materials is critical, especially given their widespread use in various technologies, from smartphones to renewable energy systems.

The implications of this research extend beyond environmental benefits; they also offer a substantial economic incentive for the recycling industry. As highlighted by research contributors Shichen Xu and Bing Deng, this novel method addresses the dual challenges of material shortages and environmental impact, presenting a win-win scenario for both industry and ecology. The adoption of such technologies could revolutionize the recycling landscape on a global scale, promoting not only sustainability but also resilience in supply chains affected by geopolitical tensions and resource scarcity.

The innovative recycling technique developed by the team at Rice University exemplifies the intersection of science and sustainability. As economies become increasingly reliant on technology, the importance of efficient e-waste recycling cannot be overstated. With further research and potential adaptations of this breakthrough method, we may pave the way for a future where electronic waste is viewed not as a problem but as a valuable resource, underscoring the significant role that innovation plays in combating environmental challenges.

Leave a Reply