In the contemporary industrial landscape, the signature byproducts of various manufacturing processes often include harmful gases, notably nitrogen oxides (NO and N2O). The presence of these compounds in emissions is not merely an environmental concern; they pose significant risks to human health and ecological systems. Nitric oxide and nitrous oxide are particularly notorious, with applications in fertilizer production leading to their simultaneous release. Thus, addressing these emissions has emerged as an imperative for both public health and environmental sustainability.

With increasing regulations and societal pressure on industries to adopt greener practices, technological innovations are essential. Among these advancements, zeolite-based catalysts have risen to prominence as effective agents for trapping and converting nitrogen oxides into less harmful forms. Recent research from the Paul Scherrer Institute (PSI) has elucidated the intricate mechanisms that underpin the effectiveness of these zeolite catalysts, revealing enhancements that could lead to even greater efficiency in the future.

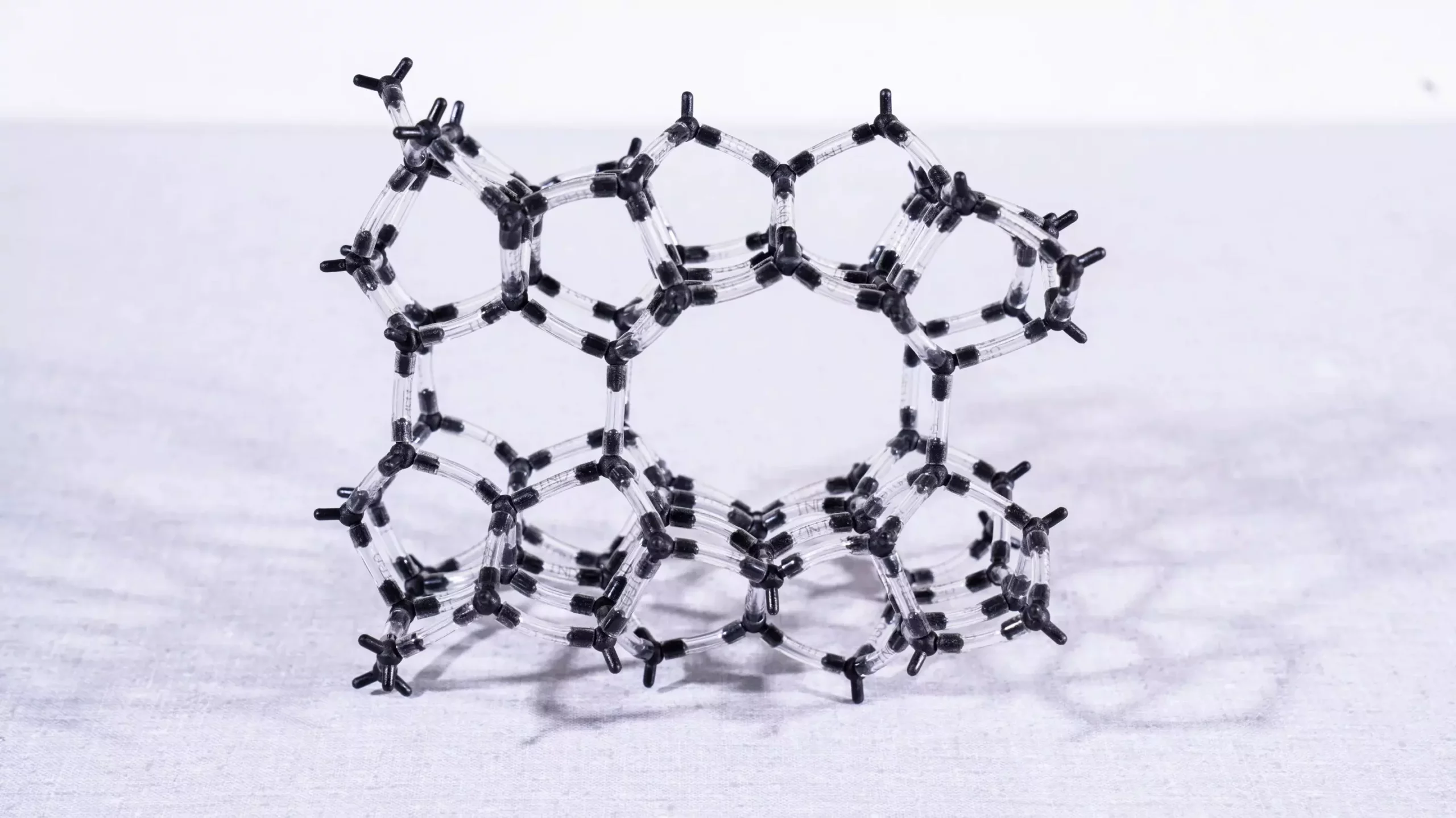

Zeolites, composed primarily of silicon, aluminum, and oxygen atoms, serve as a framework for catalysis. They can be found both in natural forms—such as minerals in rocky terrains—and as synthetically produced counterparts tailored for specific industrial applications. The unique nano-porous structure of zeolites allows them to host various metal atoms, with iron being a critical component in catalyzing the conversion of nitrogen oxides.

Researchers have identified that iron can exist in multiple forms within zeolites—ranging from isolated atoms to clusters of several iron atoms. This structural variability raises questions about the specific configurations that facilitate effective catalysis. The recent findings by the PSI team emphasize that while many iron species can be present, only certain arrangements yield significant catalytic activity.

Dissecting the Catalytic Mechanism

To clarify the interactions that lead to effective catalysis, a series of sophisticated spectroscopic analyses were conducted. Using the Swiss Light Source (SLS), researchers employed X-ray absorption spectroscopy to provide a comprehensive view of the different iron species during the catalytic process. This multi-faceted approach was further complemented by techniques such as electron paramagnetic resonance spectroscopy and infrared spectroscopy, allowing scientists to probe the contributions of each iron species involved.

The crucial revelation from this investigation centers on the interaction between specific iron atoms within the zeolite structure. The researchers discovered that two neighboring iron atoms play a pivotal role in facilitating the transformation of NO and N2O. One atom interfaces with nitrous oxide through a square arrangement of surrounding oxygen, while the other engages nitric oxide via a tetrahedral formation. This cooperative behavior between the two iron sites underlines the necessity of precise spatial configuration within the zeolite matrix for effective catalytic action.

The significance of efficiently removing nitrogen oxides from industrial emissions cannot be overstated. Both NO and N2O have severe implications for air quality and climate change. Nitric oxide contributes to the formation of acid rain, negatively affecting ecosystems and human health, while nitrous oxide is a potent greenhouse gas, with a global warming potential nearly 300 times greater than that of carbon dioxide. Consequently, advancing catalysts that can effectively neutralize these gases is a crucial step toward sustainable industrial practices.

The innovative findings from the PSI not only enhance our understanding of the underlying processes involved in zeolite catalysis but also open avenues for the design of improved catalysts. Insights gained regarding the specific active sites within the zeolite framework can guide the development of next-generation materials that maximize catalytic performance.

As the world moves closer to stricter environmental mandates, optimizing zeolite-based catalysts will play a critical role in industry compliance and environmental stewardship. By refining manufacturing processes to focus on the active sites identified in recent research, industries can significantly enhance the effectiveness of nitrogen oxide removal. The potential for new, more capable catalysts offers a promising path toward achieving robust emission reduction while ensuring that industrial growth does not come at the expense of health or environmental integrity.

The collaborative research endeavors at institutions like the Paul Scherrer Institute signify the forefront of innovation in combating industrial emissions. The intricate understanding of catalyst behavior can lead to groundbreaking, sustainable shifts in how industries address their environmental impact. With continued exploration and refinement of these catalysts, a cleaner and safer future becomes increasingly attainable.

Leave a Reply