Biological systems have long inspired researchers in various scientific fields due to their remarkable ability to produce materials that exhibit both strength and resilience. The unique structures found in nature, such as those in sea sponges, illustrate this concept perfectly. These organisms grow by layering different materials, strategically integrating stiff and soft components. This not only allows them to withstand significant stress but also provides flexibility, showcasing a sophisticated balance that synthetic materials often struggle to replicate. As Nancy Sottos from the Beckman Institute eloquently states, “Nature has a way of turning brittle materials into tough ones through intricate patterning.”

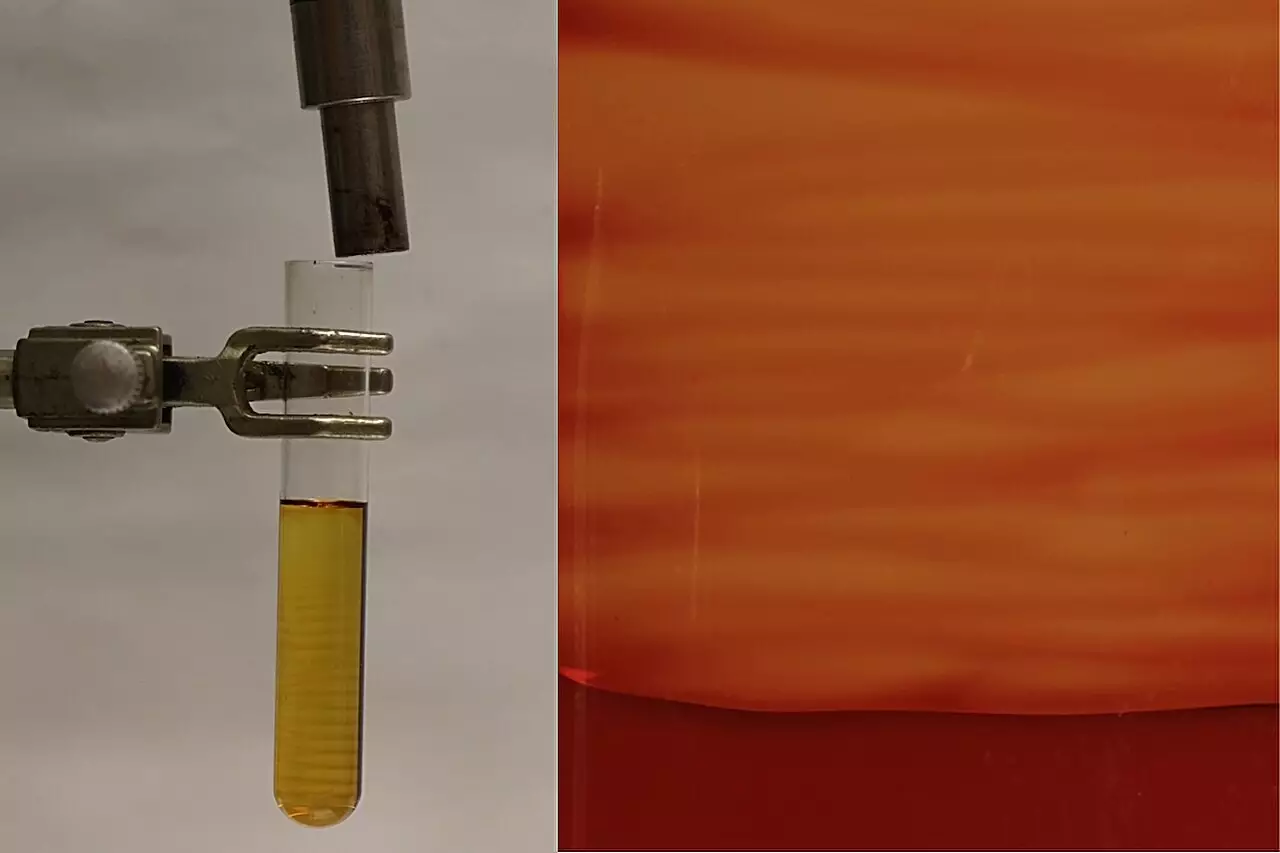

In a groundbreaking study published in the journal Nature, Sottos and her team explored a method known as frontal polymerization for creating synthetic materials that mimic biological patterns. This technique leverages heat to initiate a chemical reaction, forming polymer networks that can be tailored for specific applications. Building on previous research demonstrating the reliability of frontal polymerization, this new work emphasizes the controlled formation of crystalline patterns within the fabricated materials. The resulting structures possess enhanced toughness and durability, akin to the complex patterns observed in natural organisms.

Jeff Moore, a researcher contributing to this project, highlighted the contrast between nature’s often chaotic patterning processes and the systematic approaches typically employed in synthetic material development. His insights underscore a fresh perspective on how we might harness spontaneous spatial arrangements to create materials with superior properties. By eliminating the need for molds or milling, they introduced a novel paradigm of material structure that leads to unique physical characteristics.

From Concepts to Creation: The Morphogenic Manufacturing Technique

The innovative morphogenic manufacturing technique utilized in this study involves minute alterations to chemical reactions, leading to the emergence of crystalline patterns. Justine Paul, a key figure in the project, reflected on the challenges faced by the team to identify optimal conditions for achieving these patterns. The pursuit of understanding the intricate spin-mode dynamics inherent in the material formation proved to be a rewarding endeavor, representing a fundamental shift in how synthetic materials can be engineered.

The outcome of their work was a hybrid material, incorporating both amorphous (unstructured) elements and crystalline domains. This amalgamation of rubbery and rigid characteristics not only enhances the resilience of the product but also opens new avenues in material design. The significance of defining the architecture of such polymers is underscored by the collaborative efforts at the Beckman Institute.

The success of this endeavor was not solely the result of individual contributions but rather the product of extensive interdisciplinary collaboration. Cecilia Leal employed advanced X-ray scattering techniques to investigate how polymer chains orient within the patterned materials, emphasizing the need to understand the intricate structure-property relationships at play. Her observations contributed to a more comprehensive understanding of how different molecular arrangements affect the performance of the final material.

Philippe Geubelle, an aerospace engineering professor, played a pivotal role in modeling the manufacturing process. His focus on addressing thermo-chemical instabilities during the production stages was crucial in facilitating the emergence of the innovative heterogeneous materials. This interplay between experimental and theoretical researchers across diverse fields—including chemistry, materials science, and mechanics—highlighted the synergistic benefits of a collaborative research environment.

As we move forward, the work done by Sottos, Moore, Leal, and Geubelle lays the groundwork for future innovations in synthetic materials inspired by nature. Their research not only demonstrates the potential of using biologically-inspired design principles to create high-performing materials, but it also illustrates the necessity of fostering interdisciplinary collaboration to tackle complex challenges in material science.

By continuing to explore and replicate the ingenious designs found in nature, we stand on the brink of a new era in material development—one characterized by enhanced durability and multifaceted functionality. Such breakthroughs not only have profound implications for industries ranging from aerospace to consumer goods but also remind us of the invaluable wisdom embedded in nature itself.

Leave a Reply