NCM811 (nickel-cobalt-manganese) materials have emerged as a top choice for cathodes in high energy density lithium-ion batteries. While their high capacity and efficiency make them appealing for various applications, they are plagued by a significant drawback: the development of cracks in poly-crystalline structures due to mechanical stress. This phenomenon poses a substantial threat to the longevity and performance of batteries, as it accelerates the loss of active materials crucial for effective operation. Thus, grasping the chemo-mechanical dynamics of NCM811 materials is essential for enhancing battery longevity.

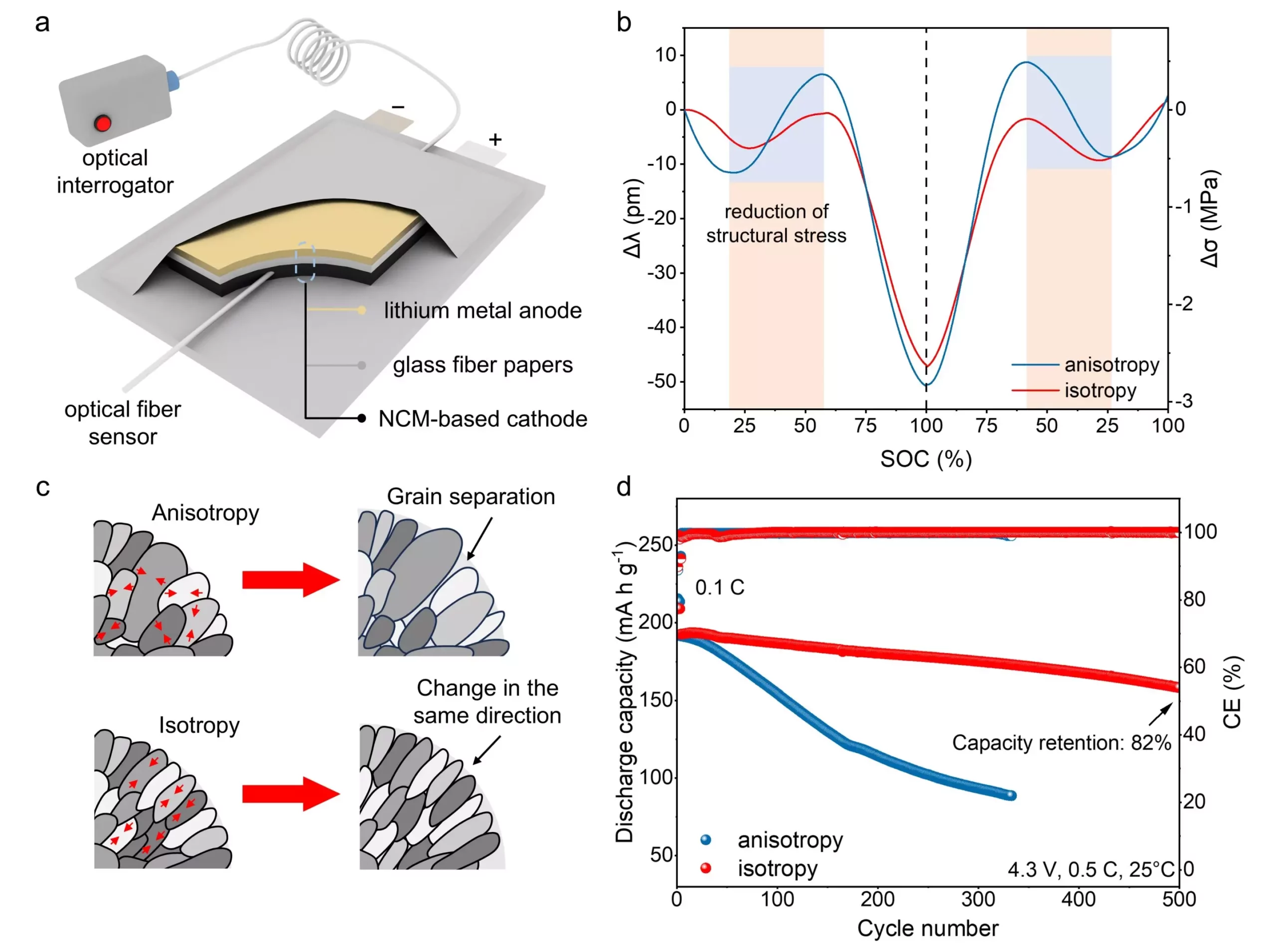

To tackle this pressing issue, a research team led by Professors Yunhui Huang and Zhen Li has pioneered the use of optical fiber for in operando stress detection in NCM811 cathodes. Their innovative integration of optical fibers with battery systems has paved the way for real-time monitoring of stress at the material level. The optical fiber’s diminutive size and inherent chemical stability ensure minimal disruption to battery performance and offer an efficient transmission of sensory data, marking a breakthrough in battery diagnostics.

The stress evolution observed in poly-crystalline NCM811 materials can be categorized into two main types: chemical stress and structural stress. Chemical stress arises naturally during the (de)lithiation process, a fundamental operation within battery mechanics. In contrast, structural stress is far more damaging, as it directly contributes to the formation of cracks that impede battery efficiency. Understanding the origins of structural stress is critical; it has been shown that structural alterations linked to nonmonotonic variations of the crystal’s c-axis during (de)lithiation significantly influence the material’s integrity.

To mitigate these adverse effects, research indicates that enhancing the anisotropy of primary particles in poly-crystalline NCM811 could yield beneficial results. By constructing an orderly arrangement of these particles, the stability of the materials under stress can be improved. Evidence suggests that a more organized structure alleviates structural stress and consequently preserves the material’s functionality. In practical terms, this approach resulted in impressive performance metrics, with a retention capacity of 82% observed after 500 cycles at 0.5C, demonstrating the potential of engineered structures for prolonged battery life.

As highlighted by Prof. Huang, the utilization of optical sensing in battery monitoring represents a transformative trend within the field. Not only does it enable the capture of intricate stress data but it also offers insights into the evolution of material properties over time. By decoding these interactions, researchers can better inform the development of more robust, safer, and intelligent battery systems. This innovation signifies a promising leap forward in the relentless quest for high-performance energy storage solutions, underscoring the essential relationship between material properties and battery performance. The integration of advanced monitoring techniques and material enhancement strategies could ultimately drive the next generation of lithium-ion batteries towards unprecedented efficiency and durability.

Leave a Reply