As summer rays intensify, the discomfort of heat—whether felt by athletes in training, children at the park, or beachgoers—grows ever more palpable. Traditional cooling fabrics often come with significant drawbacks, such as costly materials or complex manufacturing processes. However, recent research from the University of Massachusetts Amherst introduces a new, natural approach to achieving comfort in hot weather, leveraging an ingenious chalk-based coating that promises to reduce temperatures beneath treated fabrics by as much as eight degrees Fahrenheit.

The Science Behind Cooling Fabrics

The quest for effective cooling textiles confronts a range of challenges. Conventional options—some capable of reflecting sunlight or dissipating heat—rely heavily on boutique fibers or intricate production methods, rendering them less suitable for broad commercial application. Trisha L. Andrew, a chemist and materials scientist, highlights how sunlight’s ultraviolet (UV) and near-infrared (near-IR) rays easily increase the heat felt by wearers. Compounding this issue, human bodies continuously generate heat, further exacerbating discomfort.

To combat these issues, scientists are exploring materials that can both deflect the sun’s rays and promote radiative cooling, a natural process whereby heat is dissipated into space. While some approaches utilize embedded synthetic light-refracting particles such as titanium dioxide, others involve organic polymers requiring harmful perfluoroalkyl substances (PFAS). These environmental concerns have led Andrew and her team to pursue an eco-friendly textile coating that utilizes everyday materials.

The research team has embarked on an innovative approach using calcium carbonate, the principal component of chalk and limestone, combined with biocompatible barium sulfate. Inspired by historic plaster techniques used in hot climates to keep buildings cool, the researchers developed a simpler, less environmentally taxing method of applying a durable polymer coating through a technique known as chemical vapor deposition (CVD).

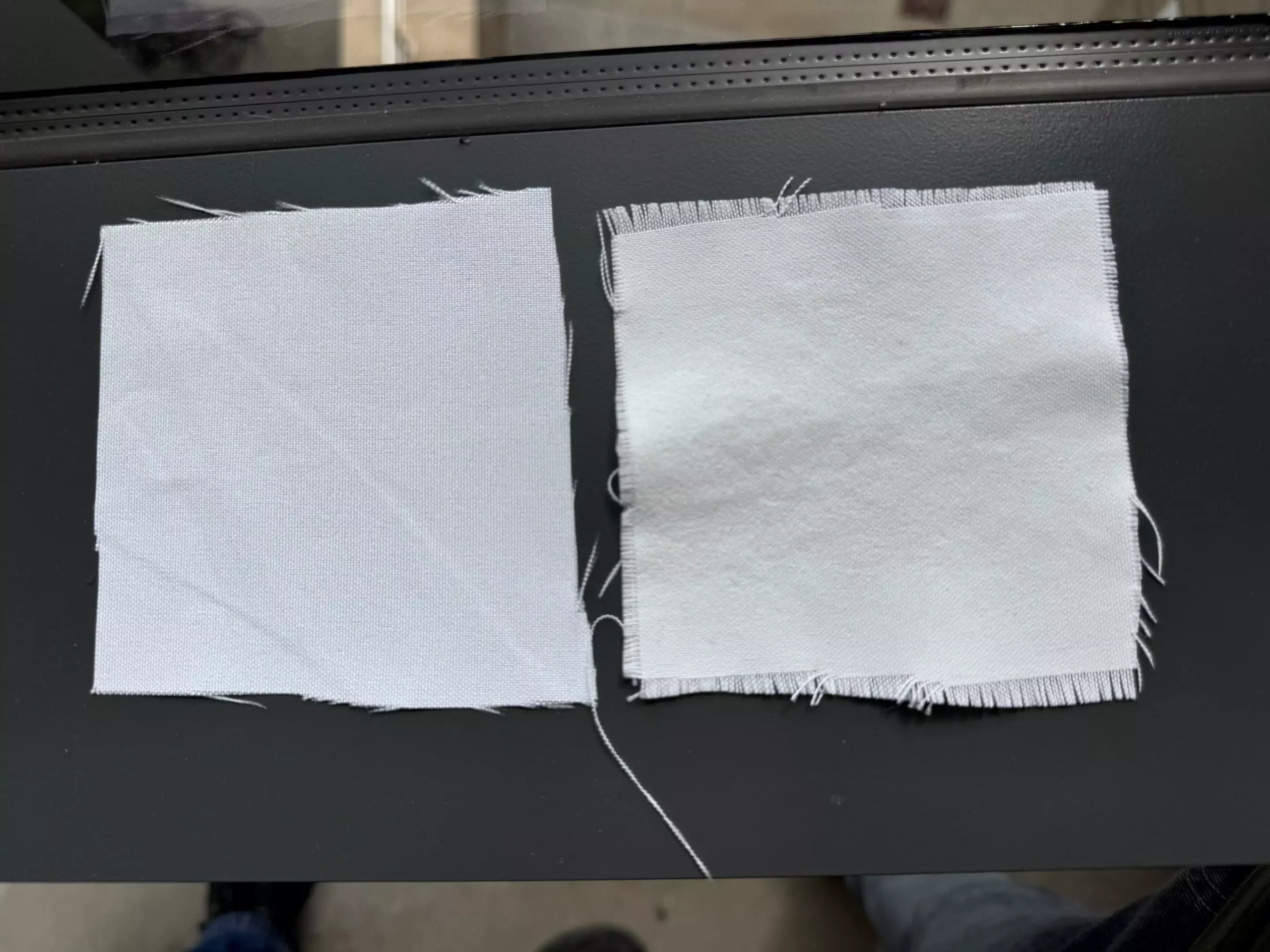

This method not only simplifies the application process but also reduces environmental impact by eliminating multiple stages typically involved in fabric treatment. The team’s coating consists of a 5-micrometer-thick layer of poly(2-hydroxyethyl acrylate). With every dip in solutions rich in calcium or barium ions and corresponding carbonate or sulfate ions, crystalline particles form, producing a chalky matte finish that captivates the eye while promising functionality.

Through meticulous experimentation, the size of these particles can be controlled to optimize their ability to reflect both UV and near-IR light. The significance lies in the precise adjustments made—monitoring dips to achieve an ideal particle size distribution can enhance the cooling effect significantly.

The efficacy of this coating was put to the test under authentic environmental conditions, specifically sunny days with temperatures exceeding 90°F. Remarkably, air temperatures beneath treated fabrics were recorded as much as 8°F cooler than the surrounding atmosphere, highlighting the material’s cooling abilities. In some cases, this temperature difference even spanned an impressive 15°F compared to untreated fabrics.

As Evan D. Patamia emphasized, these results indicate not merely a crisp solar deflection but an authentic cooling sensation, akin to the relief offered by standing in shade. Patamia’s words underscore the innovative nature of this cooling fabric—it does not rely on energy inputs but rather harnesses natural processes to mitigate heat discomfort.

The Path Forward for Cooling Textiles

Moving beyond mere concept, the research also tackled the durability of the cooling fabric. Megan K. Yee conducted tests simulating the effects of traditional laundry detergents to ascertain whether the coating would endure everyday use. Importantly, the coating exhibited resilience; it retained its cooling properties even after extensive washing.

Andrew, with aspirations rooted in sustainability, is working towards commercial viability through a startup aiming to scale the CVD process for mass production. The potential to treat large rolls of fabric—measuring five feet in width and up to 100 yards long—was highlighted as a game-changer, promising applications in various markets.

Reflecting on the broader implications, Patamia concluded that this technology can redefine comfort standards in hot weather. By transforming typical fabrics into effective cooling solutions, the team’s innovation emerges as a beacon of hope, particularly for regions grappling with climate change and extreme temperatures.

In essence, the chalk-based cooling fabric represents an exciting fusion of science and practicality, ushering in a new era that could make sweltering summers much more bearable.

Leave a Reply