Optical materials are the backbone of many technologies that we utilize in our daily lives, ranging from telecommunications to advanced display technologies like OLEDs. Their primary function is to manipulate light in various ways, which is critical for applications such as sensing, imaging, and even medical treatments. However, traditional optical materials pose significant challenges, notably their high production costs and complex manufacturing processes. Limited availability of resources, particularly rare-earth elements used in many optical applications, further exacerbates these issues, making the quest for sustainable and cost-efficient alternatives increasingly urgent.

In an exciting development, researchers at Shinshu University in Japan, led by Professor Hiroshi Moriwaki and Associate Professor Shouhei Koyama, have uncovered a novel method to create optical materials using a surprisingly mundane substance: pencil lead. This breakthrough study, recently published in *Optical Materials*, proposes a low-cost and efficient technique for tuning light reflectance spectra through the application of plasma. The use of pencil lead, composed primarily of clay and graphite, provides a unique opportunity to transform an everyday material into a functional optical component.

The key to this transformation lies in the interaction between pencil lead and plasma technology. Plasma, considered a state of matter similar to gas but with charged particles, provides a mechanism for surface alteration that allows for greater manipulation of light. This innovative approach capitalizes on the distinct physical properties of pencil lead, particularly its thin-layer interference phenomena resulting from its dual composition.

The research team’s exploration began with the premise that irradiating pencil lead with plasma could control its reflectivity in the visible spectrum, leading to the emergence of structural colors. As Professor Moriwaki explains, this phenomenon occurs when light waves interact with thin layers—specifically, the interplay between the clay and graphite constituents of pencil lead. By using plasma etching techniques to remove graphite, researchers were able to expose the underlying clay layer, thereby modifying the optical properties of the lead.

In their investigation, they experimented with varying durations of plasma irradiation, ranging from brief ten-second bursts to longer intervals exceeding three minutes. The ramifications of their findings were significant, as extended plasma exposure developed an innovative optical material capable of influencing light in the near-infrared and mid-infrared ranges—areas beyond the visible spectrum. This enhancement stemmed from an increase in the thickness of the exposed clay layer, effectively broadening the material’s optical capabilities.

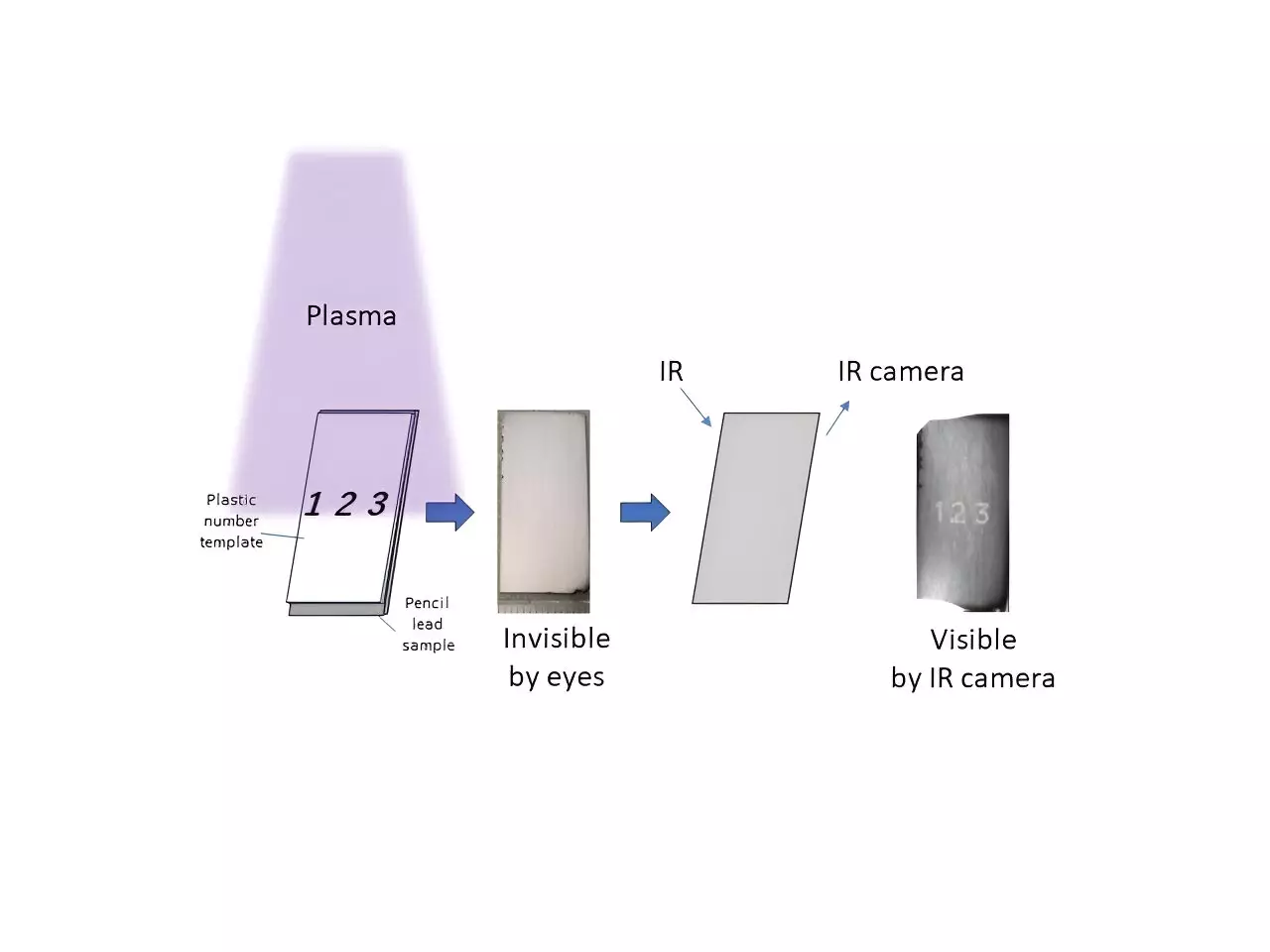

One of the most striking applications of this research involves the fabrication of invisible characters etched onto the pencil lead’s surface, discernible only under an infrared camera. This unique capability not only showcases the potential functionality of the new optical material but also hints toward practical uses in security printing and data encoding, offering avenues for innovation in various fields.

The implications of this technology are far-reaching. For instance, affordable optical materials could revolutionize existing manufacturing processes, particularly for non-mainstream applications that currently struggle under high costs. Furthermore, given the environmentally friendly nature of using pencil lead—an accessible and abundant resource—the approach offers a sustainable pathway to optical material production that counters reliance on scarce materials.

As the world gravitates toward sustainable solutions, the methodology developed by Moriwaki and Koyama holds promise not only for the optical materials industry but also for broader technological applications. Their research emphasizes the feasibility of rethinking conventional materials and methodologies in light of modern requirements for sustainability and cost-effectiveness.

The team’s ambition extends beyond academic publication; they envision real-world applications that align with emerging trends in technology and environmental stewardship. For instance, the integration of this research into 3D printing technologies could yield groundbreaking advancements, enabling the production of customizable optical components as needed, which cuts down waste and inefficiency.

The pioneering work of Professor Moriwaki and Associate Professor Koyama epitomizes the potential for innovation when traditional materials are viewed through the lens of advanced technology. Their findings not only highlight a tangible method for producing optical materials but also serve as a beacon for future research and development in sustainable manufacturing. As this field evolves, the marriage of simplicity, accessibility, and cutting-edge technology seems poised to redefine the optical landscape for generations to come.

Leave a Reply