For decades, the presence of voids or pores within materials has been regarded as a major flaw, leading many manufacturers and researchers to prioritize the elimination of these imperfections. Voids have been associated with reduced mechanical strength and durability, making them a significant concern in fields ranging from construction to electronics. Conventional approaches often involve strategies that lead to fully dense materials, where any pore or void is seen as a vulnerability that could compromise performance. In this prevailing paradigm, the quest for perfection has driven innovation, yet new research suggests that some of these assumptions may need to be reevaluated.

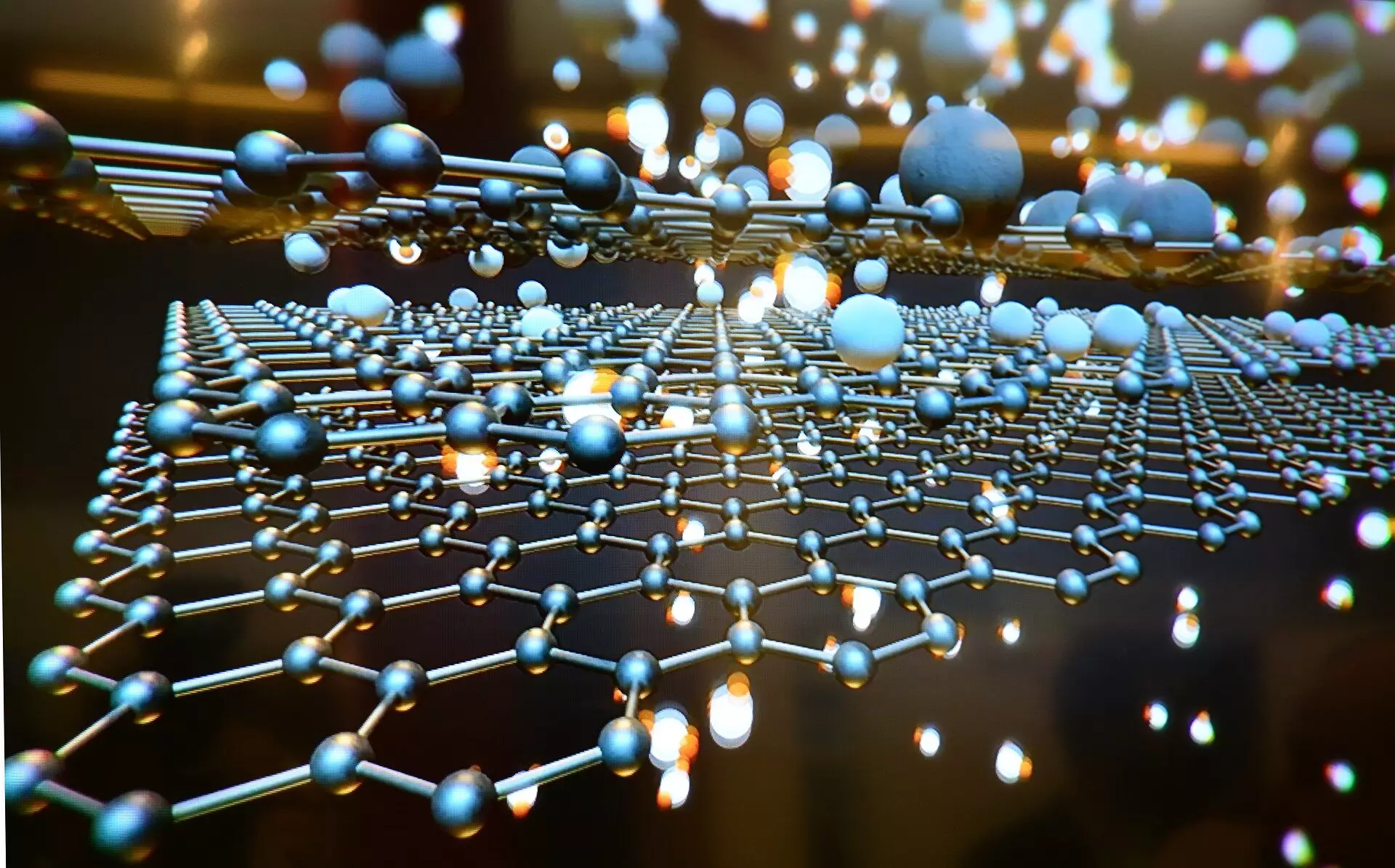

A recent study led by Prof. Jin Haijun and his team at the Institute of Metal Research (IMR), Chinese Academy of Sciences, throws a spotlight on a promising alternative. Their innovative work challenges the negative perception of voids, presenting evidence that, when incorporated strategically, voids can enhance the properties of materials. The researchers developed a revolutionary form of gold, termed nanovoid dispersed gold (NVD Au), which contains numerous nanoscale voids. This material, characterized by void sizes ranging from mere nanometers to hundreds of nanometers, demonstrated not only increased strength but also improved ductility compared to its dense counterparts.

The transformational properties of NVD Au stem from a carefully devised manufacturing process that integrates dealloying—a specific corrosion technique—with compression and thermal annealing. These methods culminate in a homogenous distribution of nanovoids within the gold matrix, which plays a crucial role in enhancing the material’s mechanical properties. Research findings indicate that NVD Au’s unique structure fosters improved dislocation-surface interactions and diminishes the likelihood of crack nucleation. As a result, this material showcases the ability to absorb greater stress and endure elongation without fracturing, a stark contrast to traditional methods that create larger, detrimental voids.

The implications of this research could be vast, extending to numerous fields that rely heavily on material performance. From portable electronics to advanced aerospace manufacturing, the potential for incorporating NVD Au in various applications could lead to the development of lighter yet stronger components. Furthermore, the study’s assertion that these enhancements occur without substantial changes to the material’s composition or phase means that the inherent characteristics of gold are largely preserved, opening avenues for new utilization that were previously deemed impossible.

This pivotal research was not a solitary venture; it involved collaboration with esteemed institutions such as the Liaoning Academy of Materials and Nanjing University of Science and Technology. This cooperative approach underscores the importance of teamwork in the realm of scientific discovery, with shared expertise leading to groundbreaking innovations.

As the traditional views on material flaws are challenged by emerging insights, it is evident that voids, if managed wisely, can offer significant advantages rather than merely represent defects. The work of Prof. Jin Haijun’s team is a crucial step toward redefining our understanding of material science, fostering an environment where innovation thrives through reassessing long-held beliefs. The future may very well be shaped by these enlightening discoveries, paving the way for a new generation of materials engineered for excellence.

Leave a Reply