Fluid manipulation is a cornerstone of modern technology, touching areas such as healthcare, pharmaceuticals, and chemical processing. Despite the advancements in solid manipulation, handling fluids continues to pose significant challenges. Recent innovations from researchers at The Polytechnic University of Hong Kong (PolyU), led by Prof. Wang Liqiu, present a paradigm shift in this area with the development of the Connected Polyhedral Frames (CPFs). This article explores the implications of this fascinating research and its potential applications across various industries.

Manipulating liquids remains inherently complex due to their unique physical properties. Traditional methods often lead to unwanted wetting or spreading, which compromises volumetric accuracy and risks cross-contamination between samples. In an era increasingly focused on sustainability, the extensive reliance on single-use plastic tools has further exacerbated global environmental issues. The emergence of CPFs offers a solution to these challenges, enabling precise, reversible manipulation of fluids without the accompanying waste.

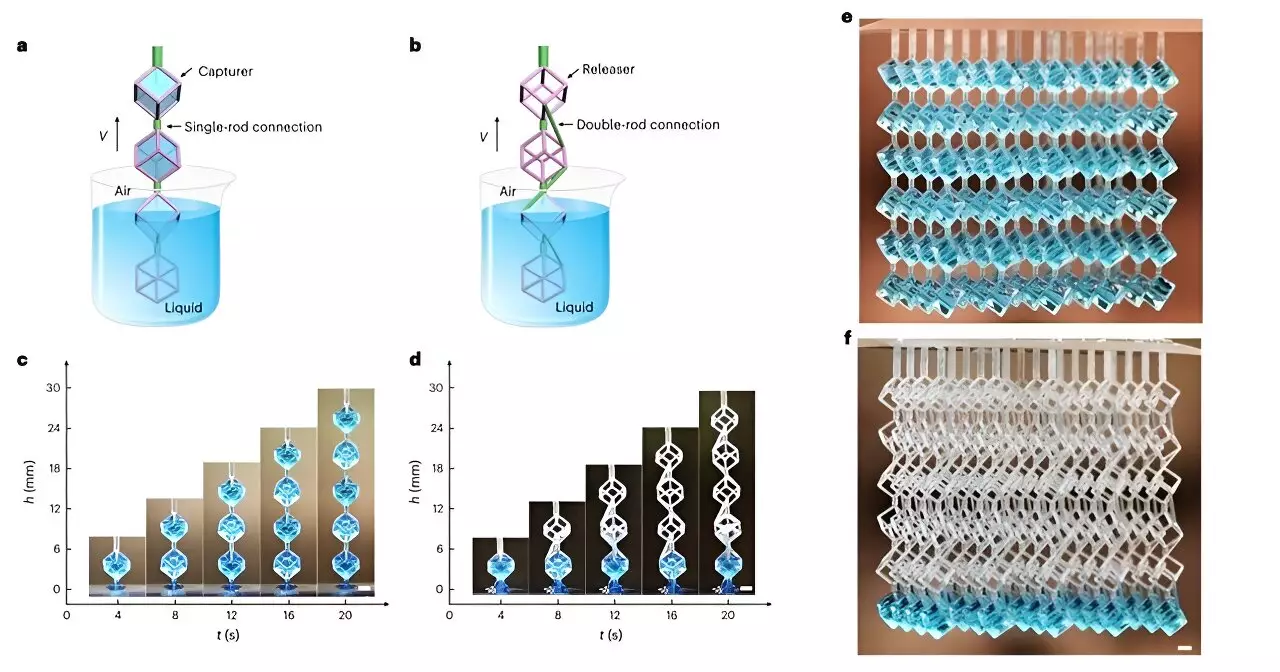

The core innovation of CPFs lies in their design, which allows users to switch fluid states from capture to release with unparalleled precision. This control is achieved through the unique configuration of polyhedral frames, enabling either fluid retention or discharge. By utilizing a mechanism based on liquid continuity, the CPFs provide a dynamic interface that adapts fluid states in real-time, thus categorizing them as a new type of meta-metamaterial.

These frames can be tuned for diverse applications, whether they are capturing liquid or facilitating release. This programmability sets the CPFs apart from existing fluid-handling technologies, addressing persistent issues that traditional methodologies have failed to resolve efficiently.

Wide-Ranging Applications in Health and Science

One of the standout features of the CPFs is their compatibility with various fluids, including aqueous solutions, biological materials, and even viscous substances. This versatility enables researchers to explore novel uses in drug delivery systems, such as the controlled release of vitamins encapsulated in hydrogels. In their study, the researchers demonstrated the differential release rates of Vitamin B2 and B12, illustrating the precise spatial and temporal control that CPFs offer.

Moreover, CPFs have proven to be valuable tools for virus detection, showcasing better performance in sampling compared to conventional swabs, which often leave residual samples. By facilitating efficient release mechanisms, CPFs could usher in a new era of diagnostic tools in virology and beyond.

Encapsulation and Environmental Management

The innovation does not stop at biomedical applications. CPFs can simplify microbial processes by enabling effective encapsulation of bacteria while separating them from byproducts. This advancement could lead to enhancements in bioprocessing applications, providing an efficient way to utilize microorganisms for valuable product generation.

Environmental concerns are also addressed through the application of CPFs for gas absorption processes. The development of a commercial-scale humidifier prototype underscores the system’s potential for greater energy efficiency and water storage capabilities. The design allows for increased surface area for liquid dispersion, facilitating effective CO2 capture and storage. This aspect of their functionality is crucial in combating climate change and exemplifies the multi-faceted potential of CPFs.

A New Frontier in Material Science

As a breakthrough in the field of fluid handling, CPFs are not merely tools but represent an evolution in material science, introducing the concept of a meta-metamaterial. By maintaining independence between the frames and their contents, the CPFs effectively realize the long-held aspiration of precision fluid transfer — akin to “scooping water with a bamboo basket.” This level of control and adaptability is set to inspire a whole new realm of scientific exploration, merging disciplines and driving innovation in technology.

The Connected Polyhedral Frames from PolyU illustrate a significant leap forward in fluid manipulation technology. By addressing longstanding issues in liquid handling with controlled encoding of fluid states and reduced environmental impact, CPFs reveal the profound implications for scientific research, medical applications, and environmental management. As the potential of CPFs continues to be unveiled, they stand to not only revolutionize fluid handling but also set a new standard for innovations in material science, closing the gap between theory and application in multiple fields. The future is indeed promising, with CPFs paving the way for breakthroughs that were once considered mere possibilities.

Leave a Reply