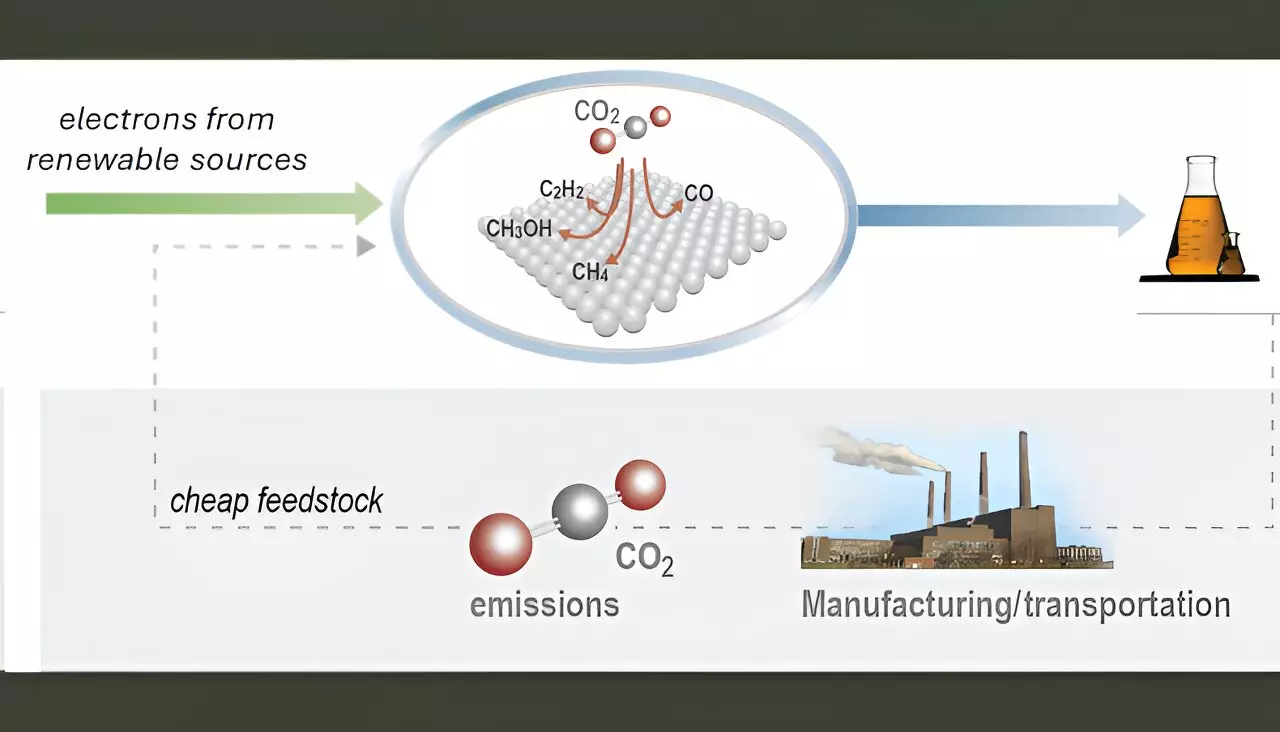

The increasing concentration of carbon dioxide (CO2) in the atmosphere has prompted urgent calls for sustainable practices in industrial processes, particularly in the production of chemicals and fuels. As the world grapples with the implications of climate change, innovative solutions that utilize renewable resources while recycling existing pollutants are sought-after. The coupling of CO2 electrochemical conversion with renewable energy sources, such as solar and wind power, offers a promising avenue for producing high-demand chemicals sustainably. Among potential candidates generated from this process, compounds like ethylene, ethanol, and acetic acid hold significant value, serving as vital feedstocks for the chemical industry and transportation sector.

Despite the promise of CO2 conversion technologies, commercialization efforts have faced significant hurdles. Chief among these challenges is the performance stability and specificity of catalysts, which are essential for efficient energy transformation in electrolyzers. These devices drive electrochemical reactions, but the efficacy of the process is heavily reliant on the characteristics of the catalyst materials employed. Traditional catalyst systems have often underwhelmed, showing inconsistency in their effectiveness due to variations in integration techniques and catalytic material formulations.

In response to these challenges, researchers at Lawrence Livermore National Laboratory (LLNL) and their collaborators have made significant strides focusing on catalyst formulations and fabrication methods. They have been developing a novel catalyst coating platform that leverages physical vapor deposition (PVD) technologies. This technique offers exceptional control over the parameters that dictate the catalyst’s overall performance—specifically its thickness, composition, and morphology. By employing PVD, the LLNL team has successfully created catalysts that exhibit increased efficiency in converting CO2 into valuable multi-carbon products.

Interestingly, while copper and its alloys have emerged as frontrunners in electrochemical CO2 conversion, the research demonstrated that fine-tuned alloy compositions can significantly impact the resultant chemical landscape, allowing for better product yields. Research lead, Juergen Biener, emphasized the scalability of this new platform, stating that it enables precise control over catalyst properties without losing essential performance aspects.

Another breakthrough in the LLNL research is the focus on copper-based dilute alloy catalysts, known for their ability to facilitate the desired reactions in a more efficient manner. These innovative catalysts can directly influence the electrochemical conversion pathway, promoting a higher yield of products like ethylene and propanol. Researchers conducted an extensive systematic exploration of these alloys, which have been notoriously challenging to synthesize using traditional methods.

The findings highlight how adjusting the energy landscape of CO2 electrolysis can effectively enhance the production of cleaner feedstocks. By using theoretical guidance to inform experimental work, scientists have been able to establish rigorous parameters around these dilute alloys to further optimize their performance. Such advancements not only pave the way for lower-cost solutions but also for more environmentally friendly manufacturing practices.

PVD methods present several advantages over conventional electrodeposition techniques, particularly in terms of waste reduction and labor intensity, despite potentially higher initial investments. The implications are vast: as the cost of renewable electricity continues to decline, integrating this technology into industrial practices could lead to transformative changes in the chemical and transportation industries.

Such innovations beckon a future where CO2 is not merely a waste product, but a viable resource for sustainable production processes. With the collaborative efforts of institutions like LLNL and various academic partners, the pathway to scaling up these technologies seems promising. The vision is clear: harnessing CO2 through cutting-edge catalysis to contribute significantly to a sustainable economy while simultaneously tackling the global climate crisis. As the development and refinement of these catalysts continue, they could very well redefine the standards for chemical production in the 21st century.

Leave a Reply