Recent breakthroughs in 3D printing technology are making headlines, particularly a groundbreaking method developed by engineers at the University of California, San Diego. This novel technique demonstrates a significant leap towards more sustainable materials manufacturing by utilizing a blend of polymer ink and a saltwater solution. By leveraging nature’s fundamental principles, this method posits an environmentally-friendly approach to creating solid structures, significantly minimizing the traditional energy-intensive processes associated with polymer solidification.

Understanding the Process

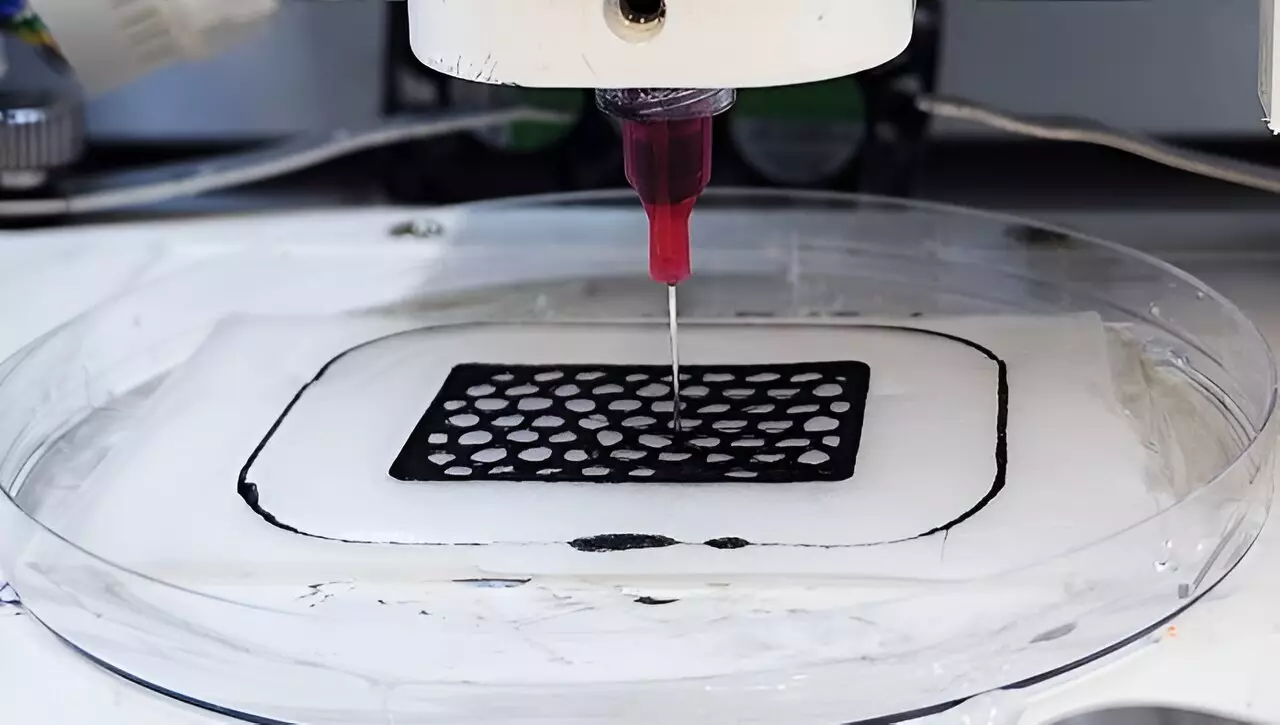

At the heart of this innovative technique is a liquid polymer solution known as poly(N-isopropylacrylamide) or PNIPAM. When this polymer ink is carefully extruded into a solution of calcium chloride, it undergoes instantaneous solidification upon contact with the saline environment. The underlying science behind this fascinating transformation hinges on the salting-out effect, wherein salt ions attract water molecules away from the polymer solution. As the water is drawn out, the hydrophobic properties of the polymer chains prompt them to condense and aggregate, resulting in a solid form.

Professor Jinhye Bae, the senior author of a study published in *Nature Communications*, emphasized the simplicity of this method: “This is all done under ambient conditions with no need for additional steps or specialized equipment.” This highlights a significant departure from conventional polymer solidification techniques that often require harsh chemicals and significant energy inputs, positioning this new method as a potentially groundbreaking solution for sustainable manufacturing.

Reversibility and Recycling: A Game-Changer

One of the most exciting aspects of this 3D printing process is its reversibility. The solid structures generated can be dissolved back into their liquid form using fresh water, enabling the same polymer ink to be reused for additional printing endeavors. This offers a simple mechanism for recycling polymer materials, a critical consideration in today’s eco-conscious context. Professor Bae noted the potential of this method to not only minimize waste but also contribute significantly to sustainable practices in polymer processing.

The researchers’ ingenuity extends beyond mere solidification and recycling. They have experimented with mixing PNIPAM inks with other materials, successfully fabricating complex structures such as electrical circuits comprising carbon nanotubes. The application of such hybrid inks demonstrates that this method is not only limited to creating simple shapes but can also facilitate the development of sophisticated electronic components. Given that these circuits are also water-soluble, they present a promising avenue for creating recyclable electronic devices, thus addressing the growing concern of electronic waste.

This pioneering work exemplifies a shift in how we think about manufacturing and materials use. By simplifying the 3D printing process and making it inherently sustainable, the research team at UC San Diego opens the door to new possibilities in polymer technology. As the world increasingly turns to eco-friendly practices, this method could very well herald a new era for polymer manufacturing, prioritizing not just innovation, but environmental conscientiousness as well. As researchers continue to refine this technique, we may see a broader adoption across various industries eager to embrace more sustainable materials solutions.

Leave a Reply