In a groundbreaking study, scientists have made significant strides in hydrogen production technology by developing a novel catalyst that mitigates the adverse effects of reverse current in alkaline water electrolysis (AWE) systems. The team, led by Professor Jeong Woo Han from Seoul National University, alongside esteemed researchers from POSTECH, including Professor Yong-Tae Kim, Dr. Sang-Mun Jung, and MSc candidate Yoona Kim, showcased their innovative findings in the prestigious journal Advanced Functional Materials. This research is not just an academic achievement; it’s a crucial step toward enhancing the viability of hydrogen as a clean energy source.

The Challenge of Intermittent Renewable Energy

Harvesting energy from renewable sources such as solar, wind, and hydropower is inherently intermittent due to dependence on environmental factors. This uncertainty poses significant challenges for energy systems aiming to rely solely on renewables. Effective storage and utilization mechanisms are essential to mitigate these fluctuations, and hydrogen emerges as a promising solution. However, the conventional methods of hydrogen production, particularly through water electrolysis, face considerable durability challenges due to fluctuations in power supply. It is within this context that the recent developments in catalyst technology become particularly relevant.

Innovative Solution: The Lead-Coated Catalyst

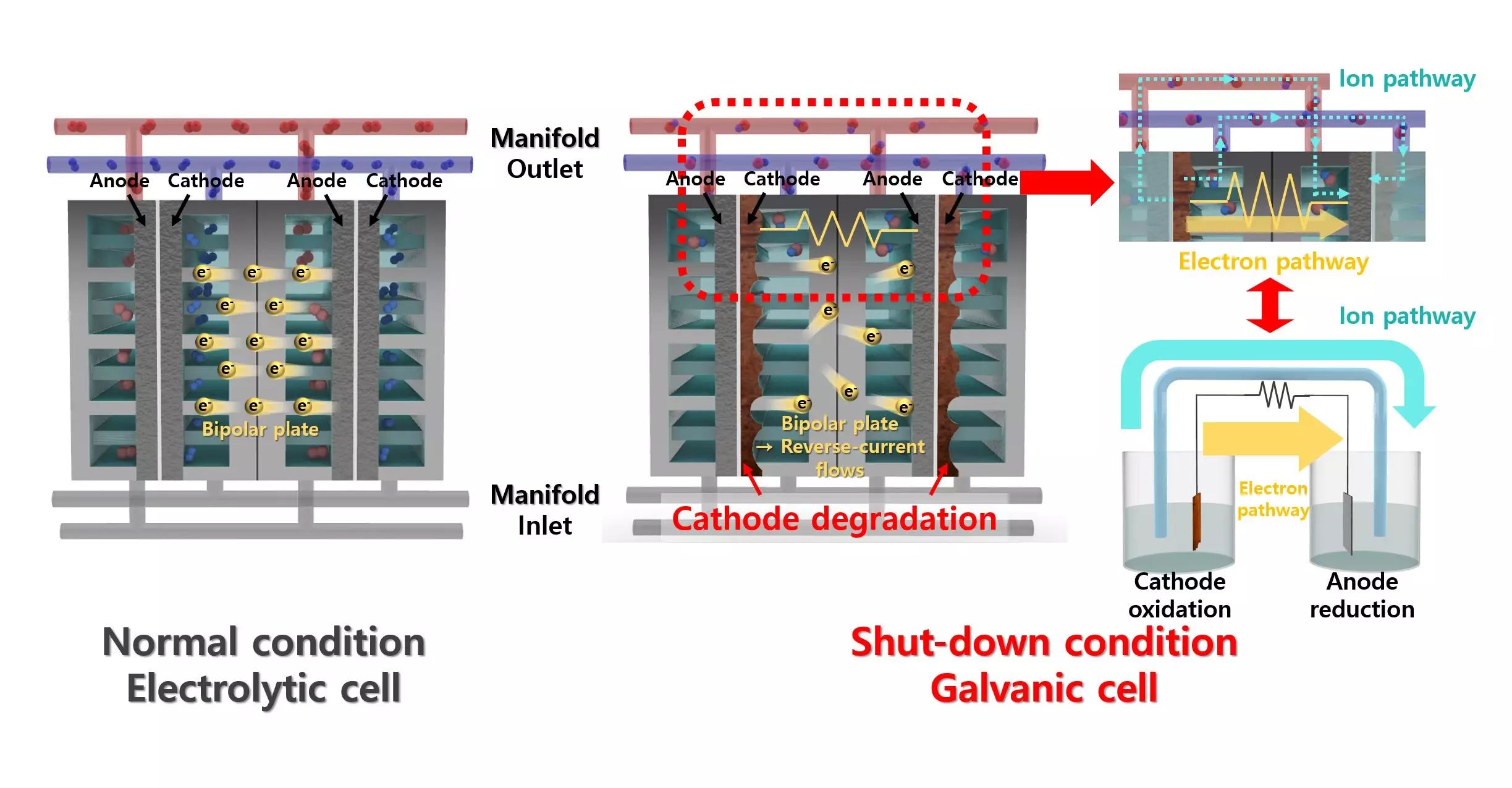

Traditional water electrolysis systems are susceptible to degradation, especially when reverse currents occur during periods without power supply. By introducing a lead (Pb) coating to a nickel (Ni) catalyst, the research team has circumvented this issue. This innovative approach is not merely about applying a new material; it’s about rethinking the role of lead in hydrogen evolution reactions. Typically considered ineffective due to low activity, lead has been strategically utilized here to enhance proton desorption and facilitate water dissociation, drastically improving the overall efficiency of hydrogen production.

Testing the Catalyst’s Resilience

One of the compelling aspects of this study is the catalyst’s robust performance during trials simulating real-world conditions. Through repetitive cycling of power supply, the lead-coated nickel catalyst exhibited remarkable resistance to the degradation usually triggered by reverse currents. This resilience signals a potential paradigm shift in AWE systems, where the need for extra protective equipment becomes obsolete. Such advancements not only simplify the hydrogen production process but also reduce costs, making this technology more accessible for widespread application.

A Vision for Future Energy Systems

The implications of this research extend far beyond academic circles, offering tangible pathways to sustainable energy solutions. With the ongoing global push for greener technologies, the practical benefits of a reliable hydrogen production system cannot be overstated. By integrating innovative catalysts like the lead-coated nickel variant, we move closer to a future where hydrogen can serve as a stable and eco-friendly energy carrier. Professor Yong-Tae Kim’s assertion that this is the first of its kind for addressing reverse current degradation emphasizes the necessity of continuing innovation in energy technologies, as our world increasingly pivots toward sustainable practices.

This research not only showcases the potential of chemistry in overcoming engineering challenges but also serves as a clarion call for continued investment in renewable energy technologies. The path forward is promising, and this technology could play a pivotal role in shaping the future of energy production on a global scale.

Leave a Reply