Carbon capture and storage technology has long been considered a crucial step towards reducing carbon emissions and combating climate change. However, one of the major challenges in this field has been the development of efficient catalysts that can convert captured carbon into valuable products. A recent discovery by University of Toronto Engineering researchers may have just provided a solution to this problem.

Most existing catalysts are designed to operate with pure CO2 feeds, which means that they are not equipped to handle impurities that are commonly present in industrial waste streams. These impurities, such as sulfur oxides (SO2), can quickly degrade the performance of the catalyst, leading to a significant decrease in efficiency. This makes the process of carbon capture and storage both time-consuming and expensive.

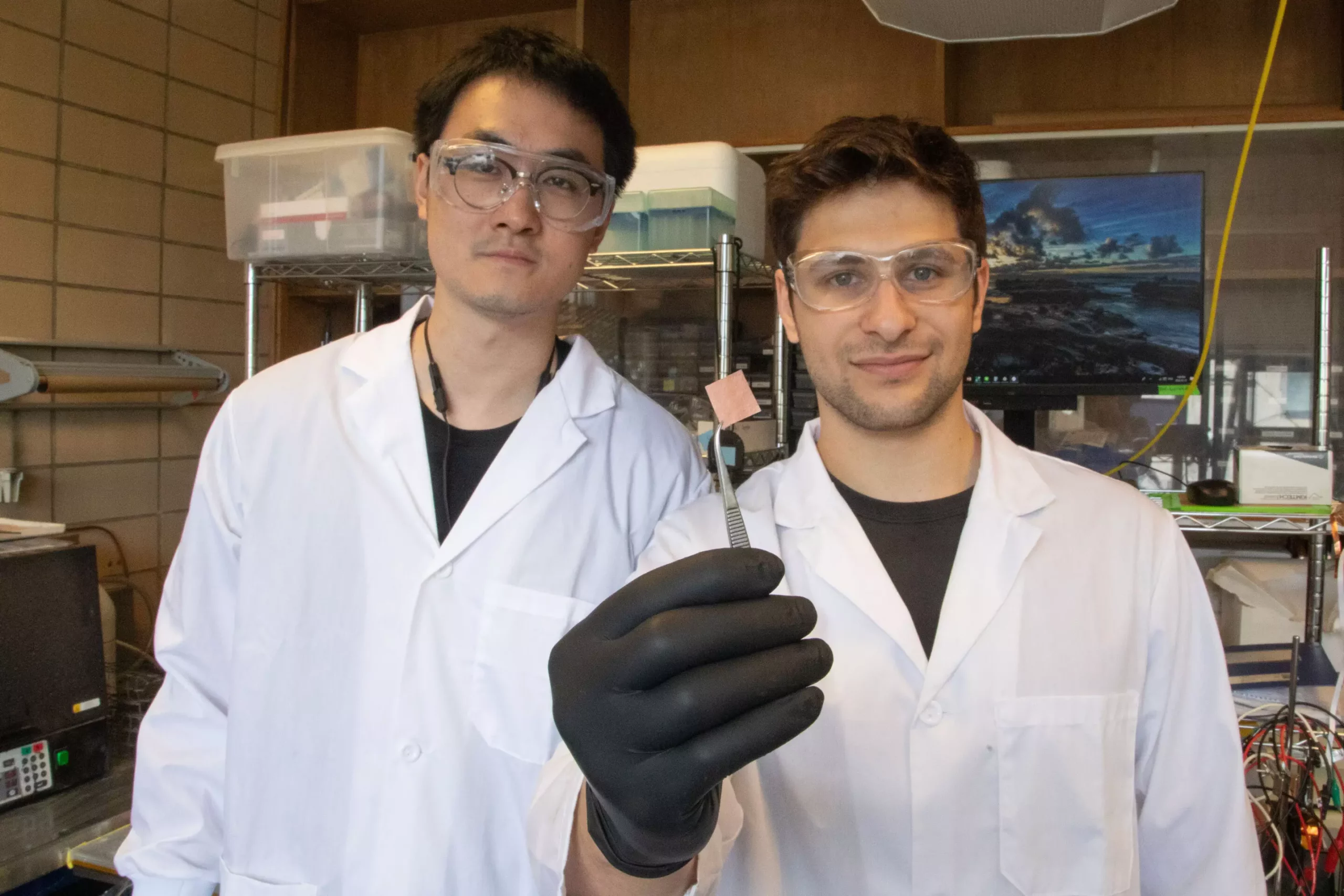

The research team at the University of Toronto made two key changes to a typical copper-based catalyst to create a more resilient version that can withstand the presence of SO2. Firstly, they added a thin layer of polyteterafluoroethylene, also known as Teflon, to the catalyst. This non-stick material alters the chemistry at the catalyst surface, making it difficult for SO2 to bind and poison the catalyst. Secondly, they introduced a layer of Nafion, an electrically-conductive polymer, which creates a barrier that prevents SO2 from reaching the catalyst surface.

When tested with a mix of CO2 and SO2, the new catalyst demonstrated remarkable performance, maintaining a Faraday efficiency of 50% for 150 hours. This is a significant achievement, considering that most high-performing catalysts can quickly lose efficiency when exposed to sulfur oxides. The success of this new catalyst design opens up the possibility of applying similar coatings to other catalysts to make them resistant to SO2 poisoning.

The impact of this breakthrough extends beyond just sulfur oxides. The research team is now turning their attention to other impurities that may be present in waste streams, such as nitrogen oxides and oxygen. By addressing the full spectrum of chemical contaminants, this new catalyst design could revolutionize the field of carbon capture and storage. The fact that this approach is compatible with existing high-performance catalysts makes it widely applicable and paves the way for more cost-effective carbon capture solutions.

The development of a more resilient catalyst that can efficiently convert captured carbon into valuable products, even in the presence of contaminants, represents a significant advancement in carbon capture technology. The University of Toronto Engineering researchers have demonstrated the potential for cost-effective and sustainable carbon capture and storage solutions that could benefit a wide range of industries. This breakthrough paves the way for a more sustainable future by providing a viable path towards decarbonizing sectors that have traditionally been challenging to address.

Leave a Reply