The growing problem of plastic waste poses a dire environmental threat, necessitating innovative solutions to manage and recycle materials effectively. Among the diverse types of plastics, polyethylene terephthalate (PET) is prevalent in various consumer products, including bottles and textiles. The pressing challenge lies in the low rates of recycling, particularly in chemical processes aimed at reverting PET to its foundational raw materials. A recent breakthrough by a team of researchers led by Professor Kotohiro Nomura from Tokyo Metropolitan University introduces a significant leap forward in addressing this issue.

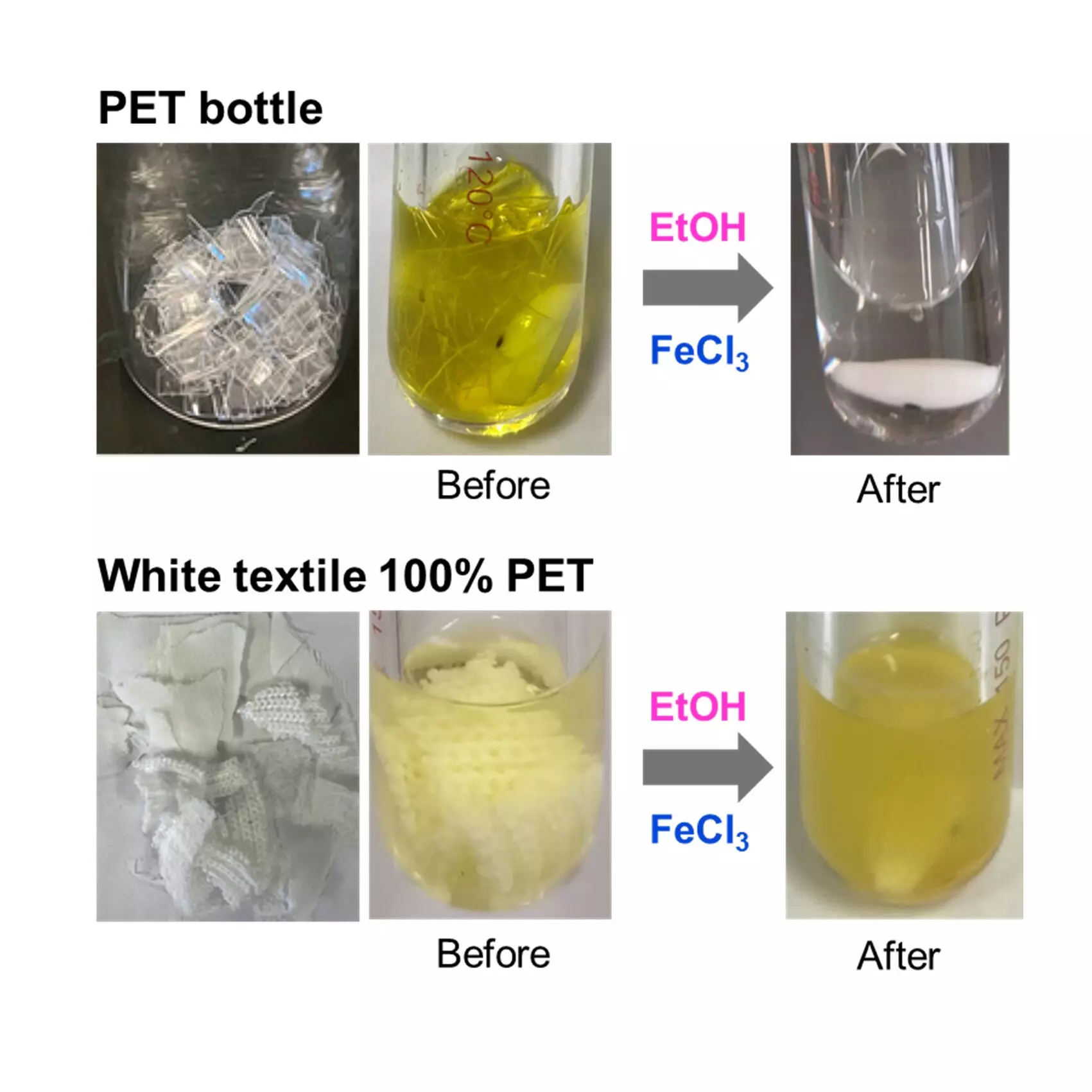

The research team has engineered a groundbreaking method that depolymerizes PET through the use of alcohols and a cost-effective iron trichloride catalyst. Unlike conventional recycling methods that require harsh conditions, such as elevated temperatures and corrosive chemicals, this new approach offers a greener and more economically feasible alternative. By deploying ethanol in conjunction with either iron trichloride (FeCl3) or iron bromide (FeBr3), the team achieved an impressive selectivity rate of 98-99%, yielding diethyl terephthalate (DET) and ethylene glycol (EG)—key products that can be utilized in the production of new materials.

The implications of this research extend well beyond the laboratory. With the world’s focus shifting towards sustainability, developing methods for the selective chemical recycling of PET could foster a circular economy in the textile and plastic industries. This technique has significant potential for recycling textile waste, which typically contains a mixture of PET and cotton. The ability to recover pure cotton fibers while efficiently depolymerizing PET from composite materials opens up valuable avenues for repurposing both materials.

Furthermore, the choice of catalyst plays a crucial role in the sustainability of this method. Iron trichloride is not only affordable but also readily available, which could enhance the scalability of this technology. This affordability stands in stark contrast to traditional titanium-based catalysts, raising hopes of wider adoption among manufacturers looking to improve their recycling processes.

With the results published in the journal *Industrial Chemistry & Materials*, the research illuminates the path toward more sustainable practices in plastic waste management. The advancement of a simple, effective, and environmentally conscious method to recycle PET has never been more urgent. This study exemplifies the strength of innovation in science leading to consequential solutions for some of our most pressing environmental challenges.

By pioneering environmentally friendly practices, researchers like Professor Nomura and his team spotlight the crucial intersection of science and sustainability. As global societal demands for effective waste management continue to rise, methods such as this will be vital in curtailing the impact of plastic pollution, propelling us towards a cleaner, greener planet. The focus now shifts to further refining these techniques, optimizing application methods, and driving their integration into the recycling industry for broader benefits.

Leave a Reply