The field of soft robotics has gained significant traction in recent years due to its potential in creating adaptive and versatile devices. Among the advancements are fabric-based soft pneumatic actuators (FSPAs), which play a pivotal role in transforming rigid robotic components into flexible, safe, and efficient systems. These actuators function by either inflating or deflating, allowing them to morph into various shapes and positions, which is critical for applications ranging from robotic grippers to wearable technology. Their inherent flexibility and lightweight design make them ideal for seamless interaction with humans and sensitive objects, thereby paving the way for safer robotic applications.

Despite their robust potential, the design and fabrication of FSPAs present myriad challenges. Traditional methodologies often rely on materials that exhibit isotropic properties, limiting the actuator’s ability to deform in controlled manners. As advancements in soft robotics continue to emerge, researchers are exploring innovative methods to enhance the performance of these actuators, particularly through automation and the integration of Turing patterns—an intriguing concept that connects mathematics with morphological development in soft materials.

Recent research published in *Scientific Reports* by a collaborative team from Toyota Central R&D Labs and Toyota Motor Engineering & Manufacturing unveils the utilization of Turing patterns as a design strategy for FSPAs. Rooted in the morphogenesis theory proposed by Alan Turing in 1952, Turing patterns arise from natural processes where the interplay of substances leads to stable, repeating designs, such as stripes on animal coats. By applying these concepts, the researchers aimed to circumvent the constraints of traditional material design and enhance the parameterization of soft actuators.

The study’s lead researcher, Dr. Masato Tanaka, emphasizes that the driving force behind this investigation stems from a pressing need within the soft robotics sector for pneumatic actuators capable of manifesting controlled movements without the reliance on specialized materials. By leveraging Turing patterns, the researchers introduced a systematic approach that enables more efficient design and fabrication processes, ultimately leading to enhanced functionality in diverse soft robotic applications.

Central to this research is the implementation of a gradient-based orientation optimization methodology. This approach facilitates the design of anisotropic materials, allowing for a varied alignment of fibers within the actuator’s fabric, thus fostering a broader range of movement capabilities. Unlike their isotropic counterparts, anisotropic materials can be engineered to respond differently under stress, ensuring that the actuator bends, twists, or expands with precision and reliability.

The process of utilizing Turing patterns commences with the optimization of fabric material orientation. By employing nonlinear finite element analysis, the research team was able to generate complex patterns from isotropic reaction-diffusion equations, which are applicable to the intricate surface topology of the actuators. This sophisticated methodological framework ensures that actuators deform predictively in response to applied pressures, marking a significant advancement over traditional design techniques that often require cumbersome trial-and-error processes.

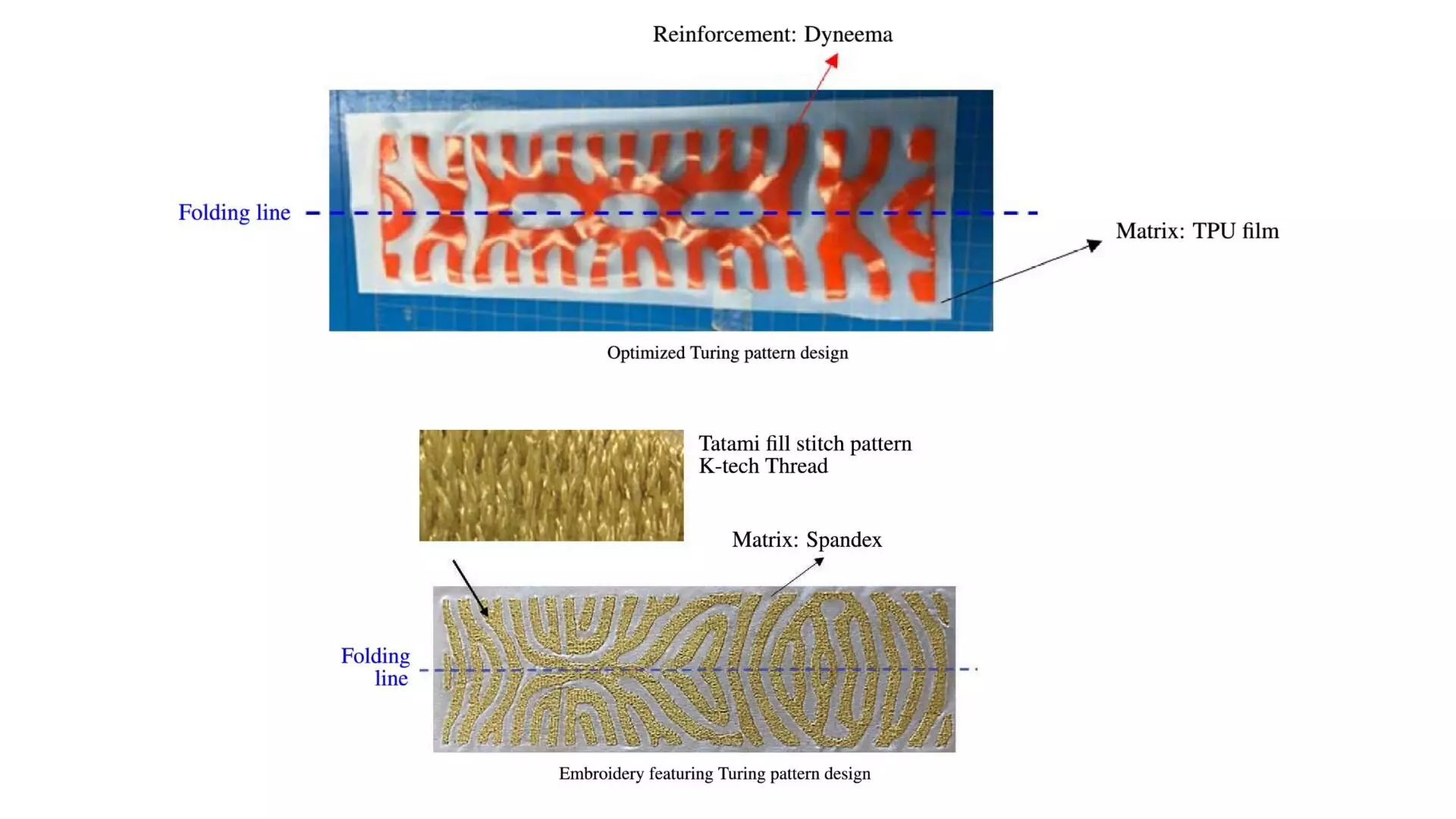

The fabrication of these innovative actuators pivots around two primary techniques: heat bonding and embroidery. In the heat bonding method, a rigid material is laser-cut into the designated Turing patterns and adhered to softer fabrics, using heat to ensure a strong bond and optimal functionality. In contrast, the embroidery method incorporates direct stitching of the Turing pattern into soft material, creating regions with different stiffness—facilitating controlled movement in response to pneumatic inputs.

One of the remarkable achievements of this study is the demonstration of scalability and cost-effectiveness in producing these cutting-edge actuators. The researchers conducted comparative analyses between their Turing pattern designs and traditional designs, revealing enhanced performance metrics. For instance, C-shaped designs benefitted from a 10% decrease in edge separation, signaling improved actuation efficiency. Moreover, while achieving S-shaped movements remains challenging in traditional designs, this new methodology showcases the potential for consistent and versatile motion with simplified pneumatic controls.

As researchers look to the horizon of soft robotics, the integration of advanced materials such as shape memory alloys and electroactive polymers may hold the key to further refining the dynamics of FSPAs. These materials could profoundly impact the responsiveness and adaptability of actuators in real-time applications, potentially leading to breakthroughs in robotics and assistive technologies.

Additionally, the research team is poised to explore automated weaving and flexible 3D printing techniques to enhance production efficiency and precision further. The drive towards mass production not only promises accessibility but aims to democratize the benefits of innovative soft robotics technologies across various domains.

The exploration of Turing patterns in the design of fabric-based soft pneumatic actuators signifies a remarkable shift in the soft robotics arena, heralding an era defined by adaptability, safety, and precision in robotic interaction.

Leave a Reply