The emergence of rechargeable solid-state lithium batteries presents a promising solution for enhancing the energy density and safety of consumer electronics. However, the environmental impact of these batteries remains a concern due to the lack of efficient recycling methods. Traditional approaches focus on recovering metals from cathodes, leaving other components to go to waste. Recognizing this challenge, a team of researchers at Penn State, led by Enrique Gomez, has developed a groundbreaking solution to address the recycling issue associated with solid-state lithium batteries.

In the current recycling process, core battery components often mix together, forming a “black mass” that contains valuable materials necessary for battery production. Separating these components from the black mass has proven to be a significant challenge, especially with the added complexity of solid electrolytes in solid-state batteries. To overcome this obstacle, the research team implemented a unique design approach to facilitate the recycling of all components of the solid-state lithium batteries.

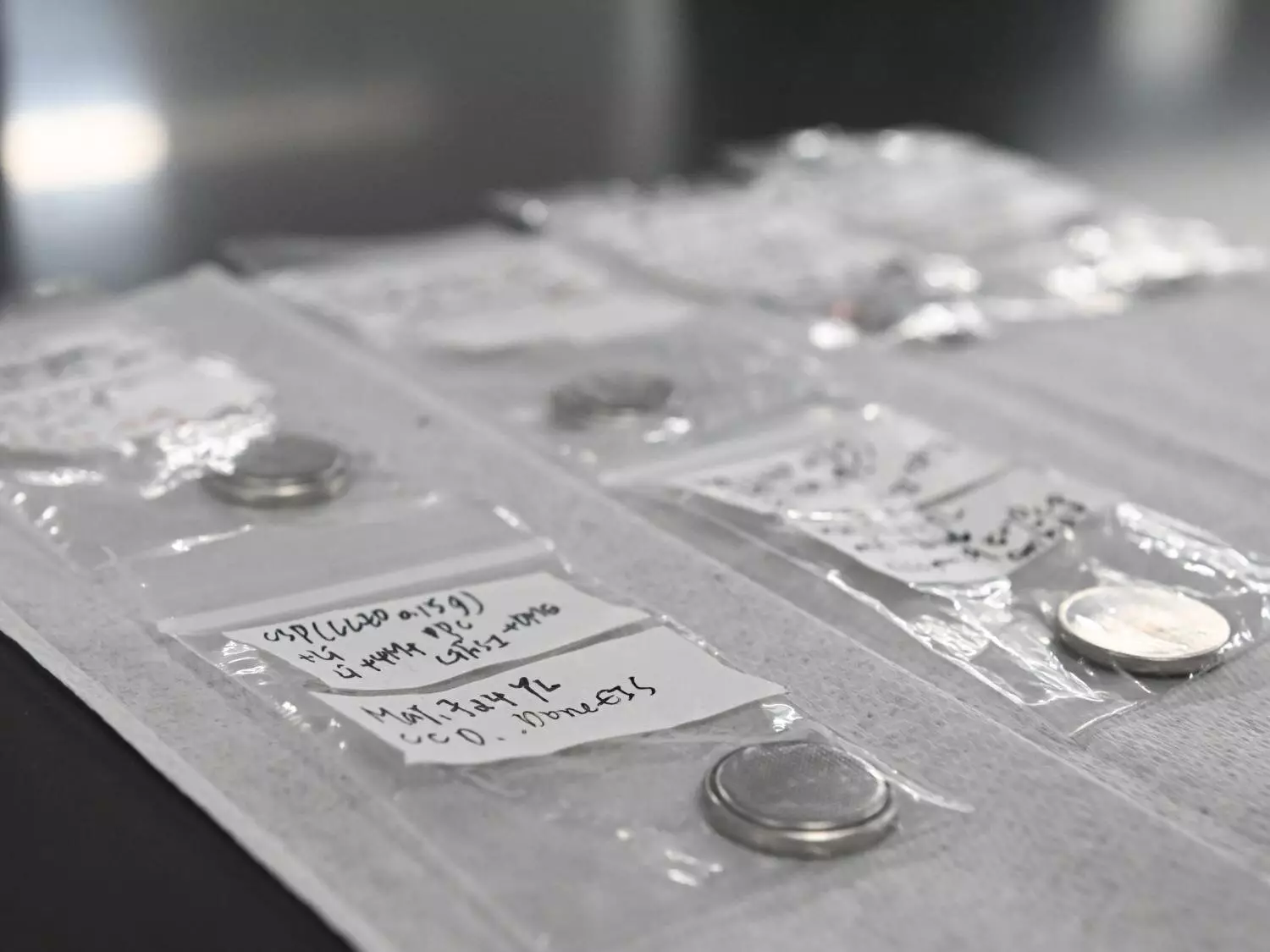

By introducing two polymer layers at the interfaces between the electrode and the electrolyte before recycling, the researchers were able to improve the separation of components during the recycling process. Dissolving the polymer layers enabled the easy separation of the electrode from the electrolyte, preventing them from mixing and simplifying the recycling process. This innovative design modification allowed for the efficient recovery of metals and electrodes from the batteries.

To further enhance the recycling process, the researchers utilized cold sintering, a technique developed in 2016, to combine the recovered metals and electrodes into a composite material. Cold sintering involves the consolidation of powder-based materials at low temperatures through applied pressure, providing a sustainable method for reconstructing the battery components. By leveraging cold sintering, the team successfully recreated the solid-state lithium batteries with the recovered materials, ensuring a closed-loop recycling system for future battery use.

After testing the performance of the reconstructed batteries, the researchers achieved an impressive discharge capacity between 92.5% and 93.8% of the original capacity. This remarkable result demonstrates the feasibility of recycling solid-state lithium batteries while maintaining high performance standards. The development of recyclable versions of these batteries opens up new possibilities for sustainable battery technologies in the future.

The innovative approach taken by the Penn State research team under the leadership of Enrique Gomez has paved the way for a more sustainable and efficient recycling process for rechargeable solid-state lithium batteries. By reconfiguring the battery design and implementing cold sintering techniques, they have demonstrated the potential for creating a closed-loop system that minimizes waste and maximizes resource recovery. With continued advancements in battery recycling technologies, the future of energy storage looks brighter than ever.

Leave a Reply