As scientists continually strive to innovate in the field of biomedical engineering, the creation of advanced materials that can safely and effectively replace or repair human tissues remains a critical challenge. Real tissues exhibit a complexity characterized by their strength, elasticity, and variable forms, making the task of replicating these biological structures immensely difficult. Recently, a groundbreaking study led by researchers from the University of Colorado Boulder, in collaboration with the University of Pennsylvania, has ushered in a new era of possibilities within this field. Their findings, published in the journal Science, introduce an innovative approach to 3D printing, promising to enhance the development of soft yet durable biomaterials fitted for various medical applications.

The quest for effective biomedical solutions runs up against the hurdle of traditional manufacturing techniques. Conventional methods like molding and casting are efficient for mass-producing identical items but falter when individual customization is required. The complexity of human anatomy necessitates a tailored approach, particularly for structures that experience significant mechanical stress, such as the heart or cartilage. The significance of customizability cannot be overstated, as each patient’s needs are uniquely different due to variations in the anatomy itself. The promising alternatives offered by 3D printing, however, provide hope for creating more adaptable versions of medical devices that can align closely with individual patient requirements.

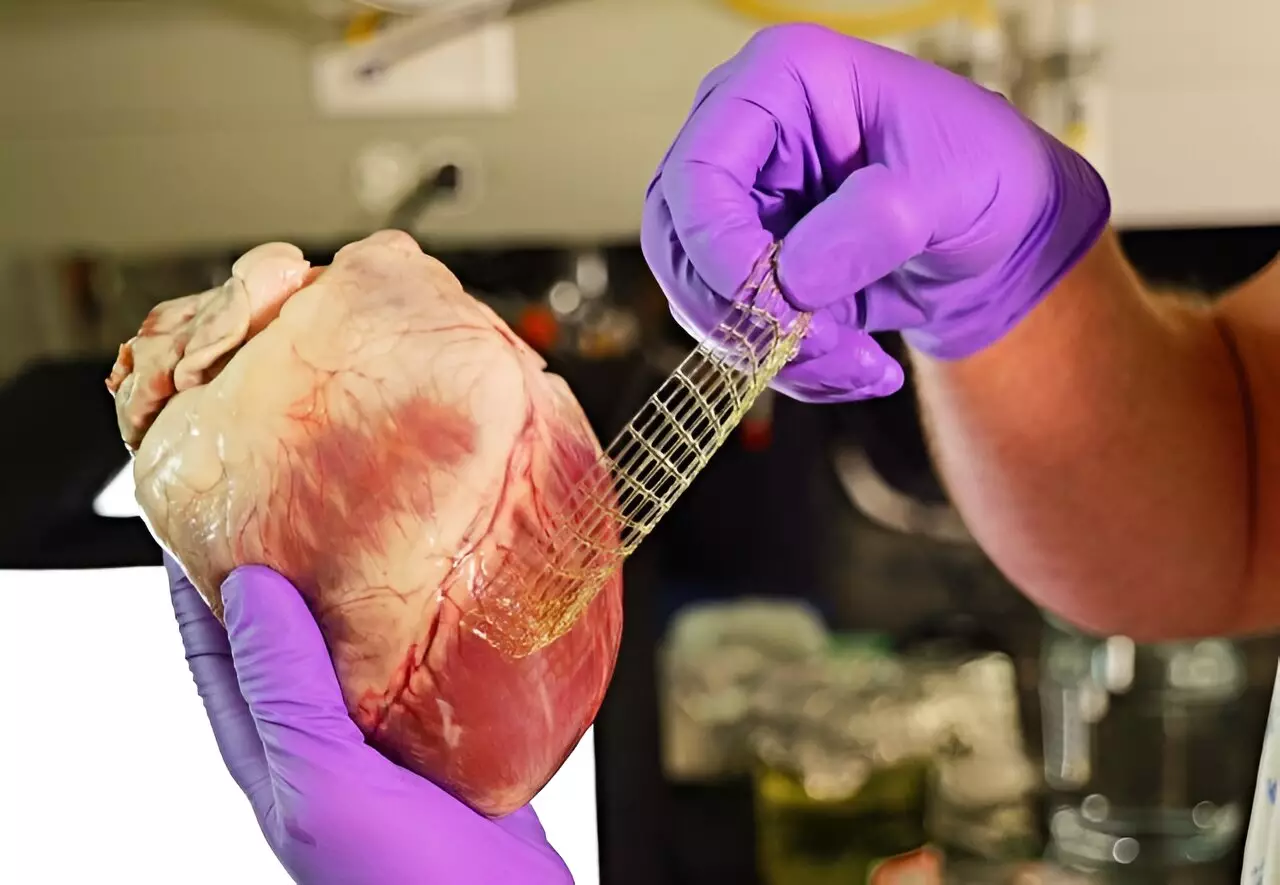

The research team’s novel 3D printing technique, aptly named CLEAR (Continuous-curing after Light Exposure Aided by Redox initiation), draws inspiration from the natural world. Notably, it mimics the behavior of worms, which intertwine themselves in ways that impart unique mechanical properties that are resilient yet flexible. The incorporation of intertwined molecular chains, known as “entanglements,” significantly improves material toughness, allowing for greater adaptability when performing in challenging environments. In laboratory tests, the materials produced using the CLEAR method demonstrated an extraordinary resilience that traditional techniques, like Digital Light Processing (DLP), failed to achieve. Their improvements in elasticity and strength inspire confidence in the potential applications of such materials.

The implications of this breakthrough extend beyond theoretical discussions; they paint a vivid picture of future medical treatments. “This research could completely change how we implement repairs in cardiac tissues or address cartilage damage,” explained Jason Burdick, one of the senior authors leading the research. For patients suffering from irreparable damage, the ability to fabricate soft, elastic materials that conform seamlessly to their physiology holds immense promise. Envision internal devices that not only adhere directly to tissues but also provide drug delivery systems to localized areas—this vision is nudging closer to reality. The potential for creating needle-free sutures that reduce tissue trauma further underscores the innovation brought forth by this research.

While the initial emphasis of this research is genuinely medical, the implications stretch beyond health care. The methodology established by the CU Boulder team offers potential benefits in both academic and industrial contexts. The groundbreaking aspect of their process is its relativity in energy consumption; the elimination of additional energy during the curing process makes it a more environmentally sustainable option. This characteristic opens avenues in manufacturing, where reducing carbon footprints is becoming an increasingly pressing concern. “There’s a significant opportunity for diverse applications in various sectors,” noted Abhishek Dhand, a lead author of the study.

A Future of Collaboration and Discovery

As the research progresses, further studies will undoubtedly illuminate how human tissues respond to these advanced materials, providing insight critical for clinical applications. The collaboration among universities and innovative research teams is paving the way for transformative advancements in medicine and technology. Additionally, intellectual property protection through provisional patents indicates a commitment to translating research into real-world applications efficiently.

In closing, the introduction of a new, robust 3D printing methodology crucially impacts the field of biomaterials, granting optimism to those with devastating tissue damage. The ability to customize and produce materials that possess both strength and elasticity is game-changing for modern medicine. Combining cutting-edge engineering with biological realities, this innovative approach may eventually lead to a substantial shift in how we understand and treat conditions affecting complex tissues. As we stand on the brink of such remarkable possibilities, the commitment to advancing research in this field promises a future where healing becomes increasingly personalized and less invasive.

Leave a Reply