The transition towards sustainable energy, particularly in the automotive sector, hinges significantly on advancements in battery technology. As electric vehicles (EVs) gain popularity, ensuring they can operate efficiently for extended durations is paramount. Structural batteries present a groundbreaking innovation in this field, blending the necessity for energy storage with the physical integrity of vehicle structures. These batteries serve dual functions: they are not only energy sources but also integral parts of the vehicle’s architecture.

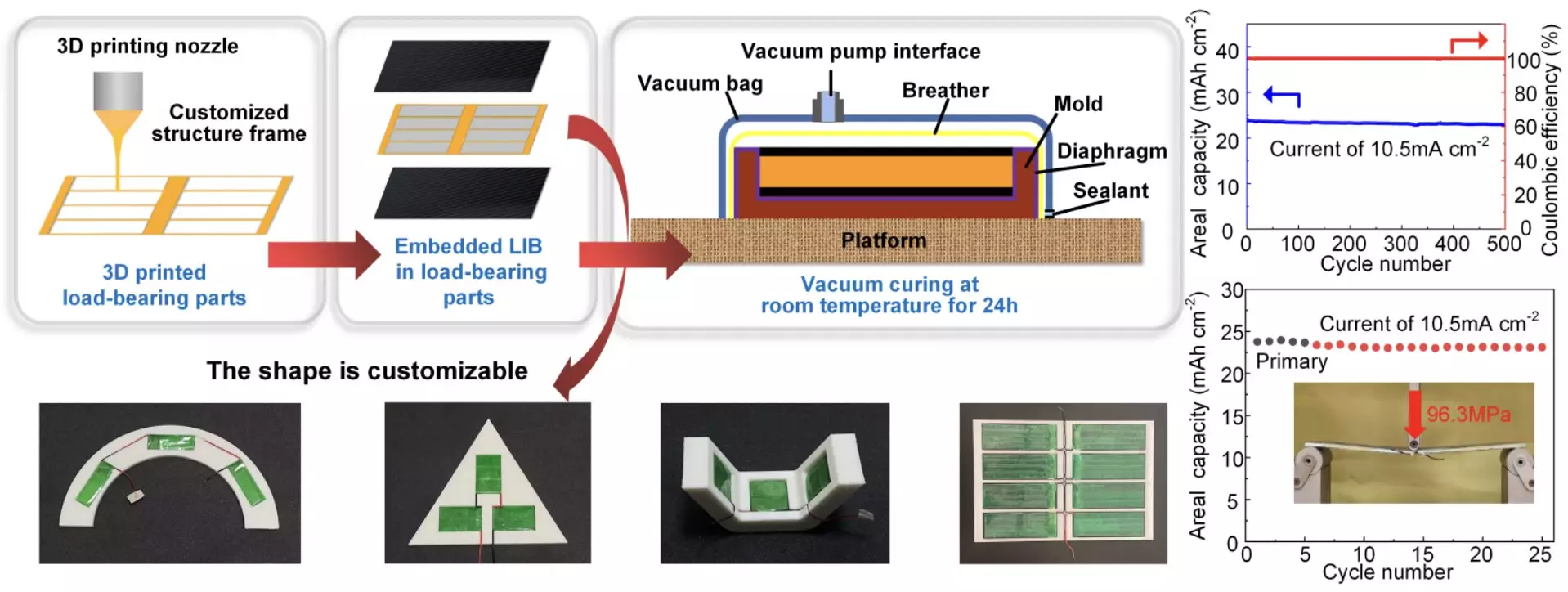

Researchers from Shanghai University have embarked on an exciting journey to unlock the full potential of structural batteries. By leveraging 3D printing technology, they aim to design and produce high-performance batteries with customizable shapes and sizes. This novel approach could be crucial for enhancing the operational range of electric vehicles and other applications. According to Yinhua Bao, the lead researcher on the project, their primary objective is to create energy storage systems that not only perform well in terms of energy density but also possess significant load-bearing capacity.

The innovative method discussed in their publication in *Composites Science and Technology* illustrates various strategies to synthesize materials suited for energy storage while ensuring the mechanical robustness of the structural components. The implications of this research extend beyond EVs, potentially impacting a variety of developments in autonomous robotics and logistics.

Despite the advances in structural battery technology, earlier models faced significant challenges, particularly concerning their energy density and mechanical performance under operational stress. Many past efforts resulted in batteries that could not withstand substantial loads and lacked longevity in performance. Recognizing these shortcomings, Bao and his team targeted the creation of next-generation structural batteries by focusing on scalable fabrication techniques, specifically utilizing 3D printing.

By adopting this modern manufacturing method, they have been able to create intricate designs that are not only customizable but also lend themselves to rapid production. Their research emphasizes the importance of the structural framework, which plays a critical role in maintaining the integrity of the battery while distributing loads effectively.

A key innovation in their approach is the concept of a decoupled structural design. This means that the energy storage unit is strategically crafted to minimize deformation under load, thus extending the battery’s lifespan and functionality. The use of finite element analysis in their studies enables them to predict how designs will behave under stress, allowing for optimizations that can significantly enhance the durability of the batteries.

Moreover, the researchers propose a distributed arrangement of the battery cells to mitigate risk; localized damage to a single battery cell won’t lead to total system failure. This foresight could significantly enhance reliability in practical applications, fostering confidence in using structural batteries across diverse environments.

Initial tests conducted on composite structural battery samples have shown promising results. These samples showcased an impressive energy density of 120 Wh/kg and 210 Wh/L. Furthermore, the longevity of these batteries has proven noteworthy, with data indicating they retain up to 92% of their original capacity after 500 cycles. Under various forms of stress, such as tensile and bending, the batteries demonstrated remarkable resilience, indicating a significant leap in performance standards.

The capacity retention metrics reveal the potential for these batteries to not only serve the present needs of energy storage but also adapt to future demands driven by technological advancements in transportation and robotics.

A Glimpse into the Future

The implications of this research are vast, particularly as we move toward a future heavily reliant on sustainable energy solutions. The 3D printing techniques developed could lead to the mass production of structural batteries tailored for electric vehicles, drones, and other robotics applications. The versatility of structural batteries places them at the forefront of renewable energy storage technologies, poised to transform how we conceive energy systems in mobility and automation.

As Bao notes, further explorations into diverse applications, such as unmanned aerial vehicles (UAVs) and other robotic platforms, are on the horizon. This research not only paves the way for innovative energy solutions but also highlights the importance of interdisciplinary collaboration in scientific progress.

The evolution of structural batteries represents a significant milestone in energy technology. By effectively integrating the roles of energy storage and structural strength, researchers are transforming design paradigms across various industries. As we advance our understanding and capabilities in this field, structural batteries may very well become the cornerstone of our energy future, promising a blend of efficiency, sustainability, and versatility.

Leave a Reply