In a groundbreaking collaboration between computer science and materials science researchers at the Department of Energy’s SLAC National Accelerator Laboratory and Stanford University, a new AI-based method has been developed to revolutionize the search for new materials. This innovative approach, detailed in a recent publication in npj Computational Materials, promises to streamline the process of materials discovery by enabling researchers to navigate complex design challenges with greater precision and speed.

Historically, materials discovery has been a time-consuming and expensive process, hindered by the immense space of possible materials and the complexity of their properties. The traditional methods of making and measuring new materials have often been slow and inefficient, particularly when faced with the challenge of matching specific research goals. For example, in the pharmaceutical industry, the task of discovering new drug-like molecules presents an astronomical number of possibilities. The need to synthesize nanoparticles with varying sizes, shapes, and compositions further complicates the process.

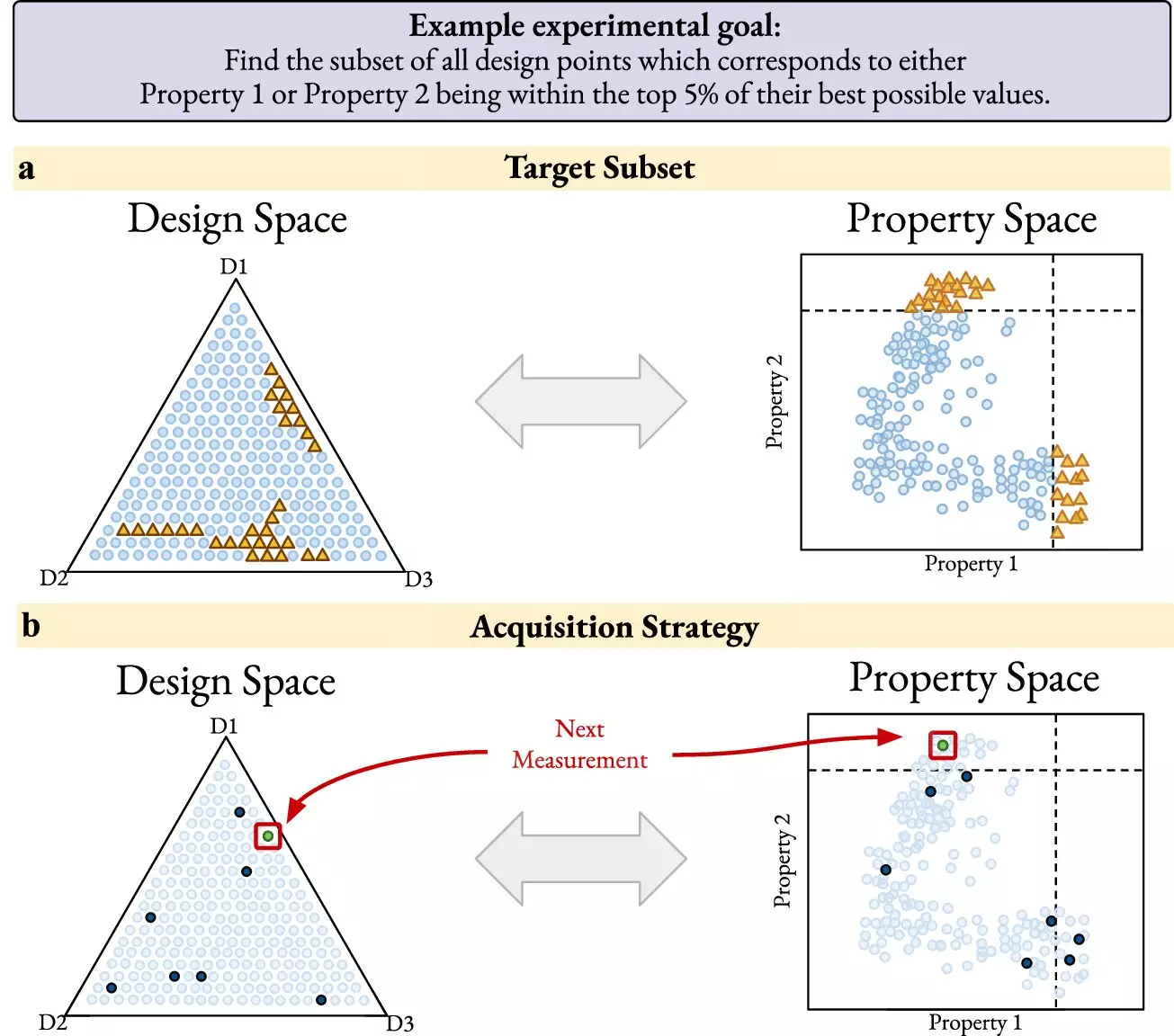

The new AI-based method proposed in the research paper introduces the concept of “self-driving experiments,” where an intelligent algorithm defines the parameters for the next set of measurements. This method allows for the rapid discovery of new materials that align with specific research goals, such as those in climate change, quantum computing, and drug design. By leveraging machine learning and algorithm development, the researchers have created a user-friendly and open-source framework that enables scientists worldwide to optimize materials design tasks over a large design space.

At the core of this innovation is the concept of Bayesian algorithm execution (BAX), which simplifies complex research goals into intelligent data acquisition strategies. This approach excels in scenarios where multiple physical properties need to be considered simultaneously, allowing researchers to capture the intricacies of materials design tasks in an elegant and straightforward manner. By learning and improving from each experiment, the AI algorithm suggests the next steps based on the data collected, making the process more efficient and effective.

The implications of this new method extend beyond materials discovery, with potential applications in catalysis, manufacturing, and healthcare. By designing materials with specific properties, such as catalytic activity, researchers can improve chemical processes, leading to more sustainable production methods. In manufacturing, the use of new materials could enhance processes like 3D printing, enabling more precise and sustainable production practices. In healthcare, tailored drug delivery systems can enhance the targeting and release of therapeutics, improving efficacy and reducing side effects.

The collaboration between SLAC National Accelerator Laboratory and Stanford University has led to a significant advancement in the field of materials science and research. By combining advanced algorithms with targeted experimental strategies, the researchers have paved the way for a new era of materials discovery. With the integration of this AI-based method into experimental and simulation-based projects, the scientific community can expect to see accelerated progress in the development of innovative materials with a wide range of applications.

Leave a Reply