A group of Australian engineers from RMIT University have developed a groundbreaking new tool for testing seabed soil in offshore wind farm projects. This device, based on a modified speargun, offers a cost-effective alternative to traditional methods of soil testing, such as winching or dropping probes from a support vessel. This is particularly useful for wind farm projects in shallower waters, where existing lightweight probes struggle to penetrate the sandy seabed and heavy-duty probes come with exorbitant costs.

The engineers conducted rigorous testing of the launching device in a controlled laboratory environment, using various probe tips and sand mixes within a water tank. By utilizing an array of sensors and high-speed cameras, they were able to capture valuable data on the device’s performance. The results of their experiments, which have been published in the Canadian Geotechnical Journal, demonstrate that the speargun device is twice as effective in penetrating the seafloor compared to lightweight free-fall soil testers. Furthermore, it offers a much more cost-effective solution compared to heavy-duty probes currently in use.

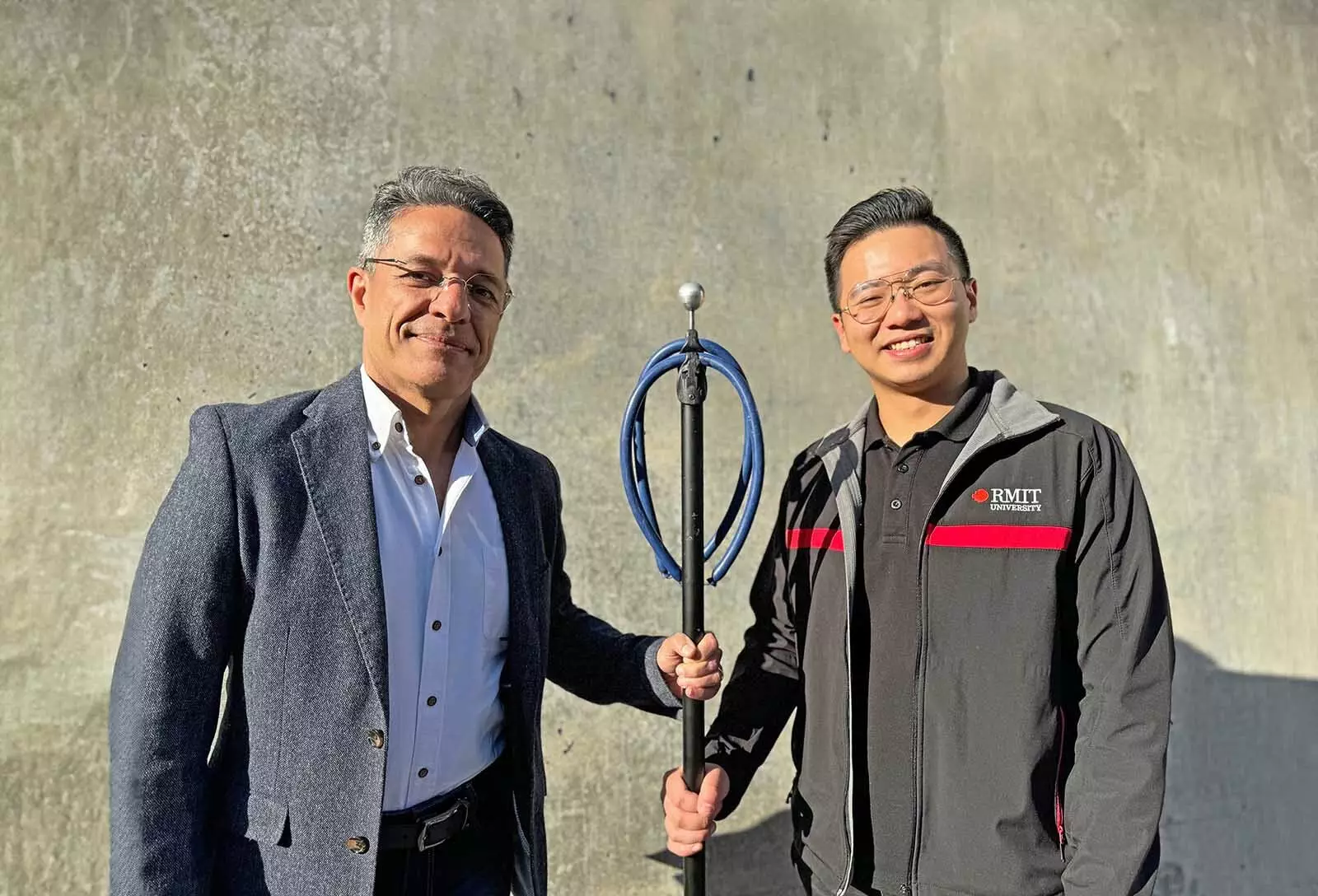

According to Junlin Rong, the Ph.D. candidate and lead author of the study, the device has shown significant potential in revolutionizing site investigations for wind farm projects. In high-density sandy material, the speargun device achieved a penetration depth that was twice that of previously reported values by freely falling probes. This breakthrough technique has the potential to provide substantial time and cost savings for engineers working on offshore geotechnical engineering applications.

Environmentally Friendly Design

One of the key advantages of the speargun device is its environmental friendliness. Probes can be easily retrieved and reused after data collection, allowing for minimal disturbance to the seabed during testing. Additionally, the device can be adapted to fit existing probes, enabling engineers to upgrade their current equipment with minimal investment. This approach not only saves time and money but also reduces the overall environmental impact of offshore wind farm projects.

The researchers are now preparing for field trials to further test the performance of the speargun device in real-world conditions. Collaborating with potential industrial partners, they aim to validate the device’s ability to achieve considerable embedment depth in dense sand. RMIT Professor of Geotechnical Engineering, Majid Nazem, emphasized the importance of these field trials in demonstrating the device’s potential for offshore geotechnical engineering applications. The goal is to streamline the soil testing process for wind farm projects, ultimately leading to substantial cost savings and improved efficiency in the industry.

Leave a Reply