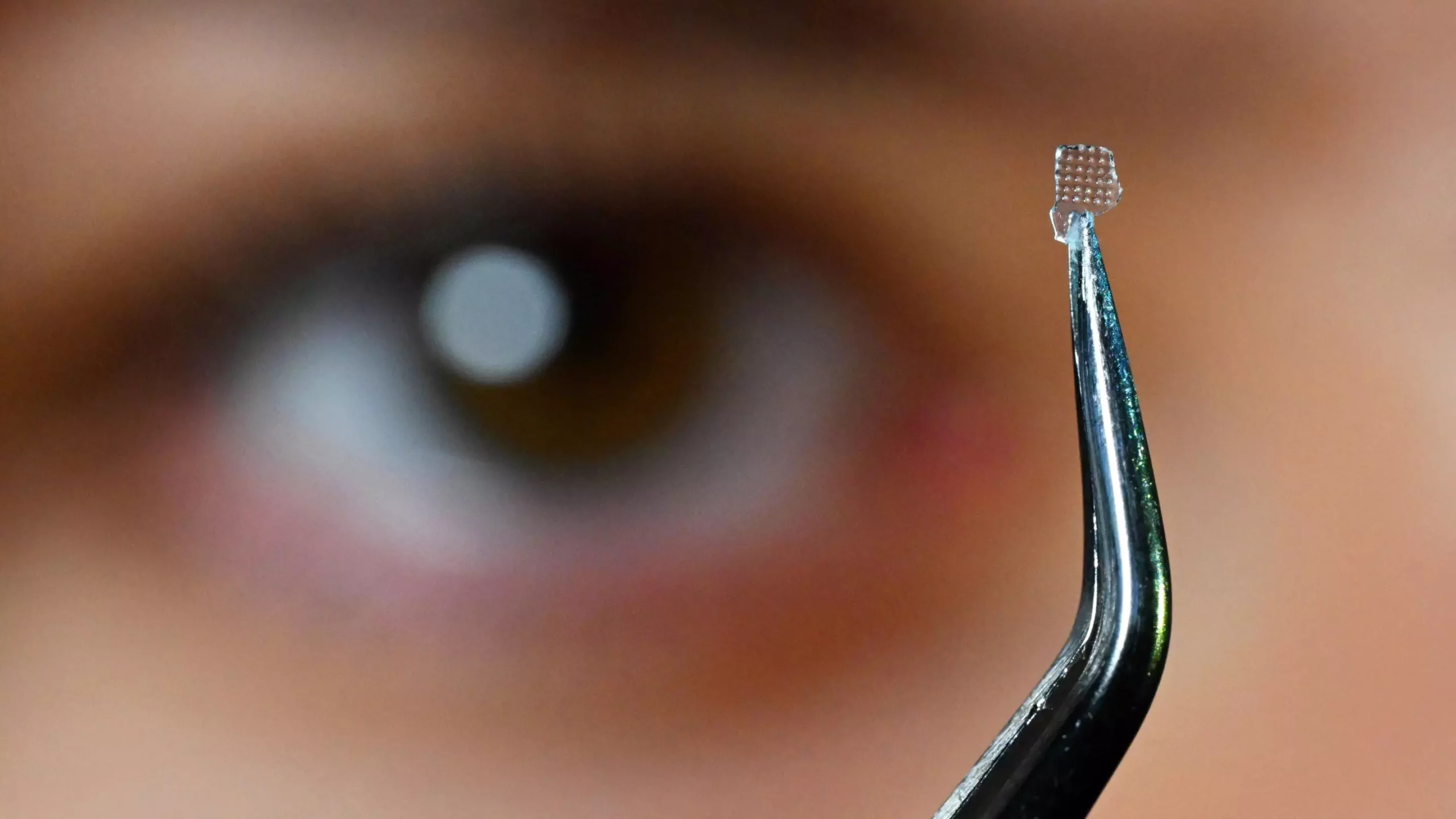

In an era where technology continues to push the boundaries of what’s possible, a team from the University of Jena has achieved a remarkable breakthrough: a miniature optical lens that alters its refractive properties based on gas exposure. This dual-functionality showcases an advancement in materials science, blending classic glass-making techniques with cutting-edge hybrid materials. The lens’s design hinges on a three-dimensional lattice structure, which creates vacancies capable of housing gas molecules. Consequently, these gas interactions significantly influence the optical behavior of this micro-lens, providing it with features unheard of in conventional optics.

The Genius Behind the Design

Professor Lothar Wondraczek, a key figure in the research, articulates the significance of developing multi-responsive materials. The lens’s ability to refract light differently based on the presence of gases opens up a new frontier in optical technology. Traditional optical lenses have always been limited by their material composition; however, by leveraging hybrid glass, researchers can design lenses that not only respond dynamically to environmental factors but also promise versatility in various applications. This capability challenges existing norms and sets a solid foundation for future innovations in the field of optics and beyond.

Challenges and Breakthroughs in Production

The creation of such advanced materials does not come without its challenges. One of the primary hurdles faced by the researchers was adapting traditional glass-forming techniques to accommodate the unique properties of hybrid materials. The use of metal-organic frameworks introduces significant complexities, as many of these materials tend to decompose when subjected to heat. Overcoming this obstacle involved meticulous experimentation, culminating in a viable synthesis process that maintains the purity of materials while allowing for intricate shaping.

Lead author Oksana Smirnova emphasizes the innovative molding process developed by the team, where melted material is introduced into 3D-printed molds, enabling a diverse range of shapes to be produced. This precision not only facilitates the manufacture of micro-lenses but also positions these materials as potential solutions for a host of applications that require acute sensitivity to environmental changes.

Potential Applications Beyond Optical Lenses

The implications of this research extend far beyond the realm of optics. Wondraczek hints at a future where these multi-responsive materials could serve in logical circuits, creating a thrilling intersection between materials science and information technology. The idea that light refraction could signal simultaneous gas absorption opens a new realm of possibilities for circuits that require dual conditions for a reaction—much like a biological system that relies on multiple stimuli for signaling.

Moreover, the lens’s capabilities might translate into inventive uses in gas containment and separation technologies, where the varying optical properties aid in monitoring and managing gas presence in industrial applications effectively. By transitioning from merely passive materials to active agents that interact with their environment, these innovations represent a vital step toward smarter technological infrastructures.

This pioneering work at the University of Jena undoubtedly heralds a significant shift toward an era of reactive optical technologies and holds the promise of transforming various industrial fields with its multifaceted approach to material science.

Leave a Reply