Piezoelectric materials serve as the backbone of a wide array of modern technologies, particularly in ultrasound and sonar applications. They generate and sense waves critical for numerous industries, including medical diagnostics and underwater exploration. However, maintaining the optimal properties of these materials has posed a significant challenge, particularly with regards to the effects of heat and pressure. Conventional practices require disassembling such devices and exposing the piezoelectric materials to extensive heat treatment—often exceeding 300°C—to restore their alignment and functionality. This lengthy and costly process not only affects the efficiency of ultrasonic devices but also renders the technology less sustainable, as it often leads to the disposal of the surrounding infrastructure when only the piezoelectric component is compromised. Researchers have unveiled a groundbreaking technique that addresses these limitations, enabling restoration at room temperature.

To grasp the significance of this advancement, one must first delve into how piezoelectric materials function. At the core of these materials’ operation is a characteristic known as “poling.” Piezoelectric substances, predominantly ferroelectric, showcase spontaneous polarization, consisting of aligned pairs of charged ions called dipoles. For optimal functioning, these dipoles must be oriented in a uniform direction. When the dipoles are aligned, the material can efficiently generate the targeted ultrasound waves necessary for practical applications. For instance, Xiaoning Jiang, a key researcher in the study, emphasizes the need for alignment: “If those dipoles aren’t in alignment, it’s difficult to generate targeted ultrasound waves with the amplitude needed for them to be practical.”

One of the significant hurdles in maintaining dipole alignment is the susceptibility of piezoelectric materials to heat and pressure. Exposure to temperatures as low as 70°C can result in misalignment of the dipoles, adversely affecting device performance. This sensitivity complicates the manufacturing process, as manufacturers must frequently either avoid certain materials or agree to processes that won’t interfere with the piezoelectric layer. Moreover, even prolonged usage of ultrasonic devices can inadvertently cause overheating, further jeopardizing the delicate poling and, in many cases, leading to inefficient or non-functional devices.

Once depoling occurs, restoring alignment requires laborious disassembly and exposure to high temperatures, necessitating costly interventions that many manufacturers and researchers would prefer to avoid.

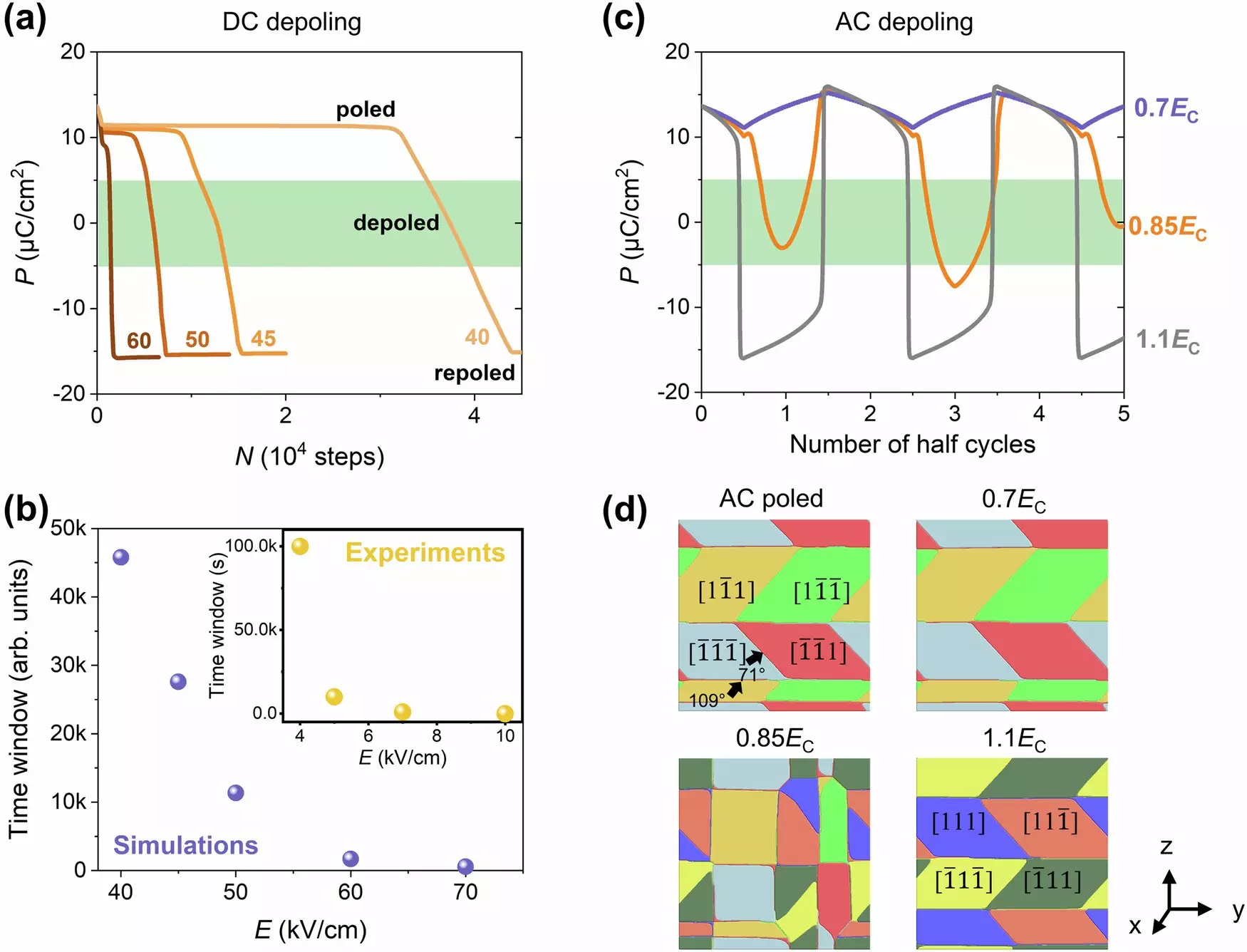

The newly developed technique that facilitates depoling and repoling at room temperature represents a monumental leap in the field of piezoelectric material applications. Instead of relying on traditional high-temperature methods, this innovative process leverages alternating current (AC) electric fields to realign dipoles without needing to disassemble the device.

Understanding the novel approach requires knowledge of existing methods: aligning dipoles with direct current (DC) is established, but its use in depoling is limited. However, the research team found that AC fields could effectively depole materials that were initially poled with either AC or DC fields. This revelation opens up new possibilities for optimizing device design and manufacturing practices.

The ramifications of this discovery are far-reaching. With the ability to maintain piezoelectric properties at room temperature, manufacturers are now liberated from the constraints of traditional heating methods and are free to explore new materials and innovative processes that could improve ultrasound device performance. Jiang highlights the potential for technological evolution: “If we can pole piezoelectric-ferroelectric materials at room temperature, it means we can alter the other materials and manufacturing processes we use when creating ultrasound devices to optimize their performance.”

This advancement could usher in a new era where the longevity and reliability of piezoelectric materials are significantly enhanced, reducing waste and contributing to a more sustainable approach in the technology sector. As industries increasingly prioritize efficiency and eco-friendliness, this breakthrough addresses both the operational challenges of piezoelectric materials and the growing demands for innovation in ultrasound technology.

The development of room-temperature techniques for restoring piezoelectric properties signifies a watershed moment in the dynamics of technological applications tied to ultrasound and sonar systems. By effectively shifting the paradigm of how piezoelectric materials are treated and maintained, this research not only alleviates existing challenges but also paves the way for future advancements that could redefine the limits of what these technologies can achieve. As further findings emerge from ongoing research, the potential to expand and enhance technological capabilities becomes ever more promising.

Leave a Reply