In an exciting development at UNIST, researchers have made significant strides in the ongoing quest for sustainable pollution reduction. Under the leadership of Professor Jaeheung Cho from the Department of Chemistry, a groundbreaking catalyst has been unveiled that closely imitates the functionality of natural metalloenzymes—nature’s own pollution fighters. This innovative work, published in the Journal of the American Chemical Society, sets the stage for potentially transformative applications in the field of environmental chemistry.

The Science Behind the Breakthrough

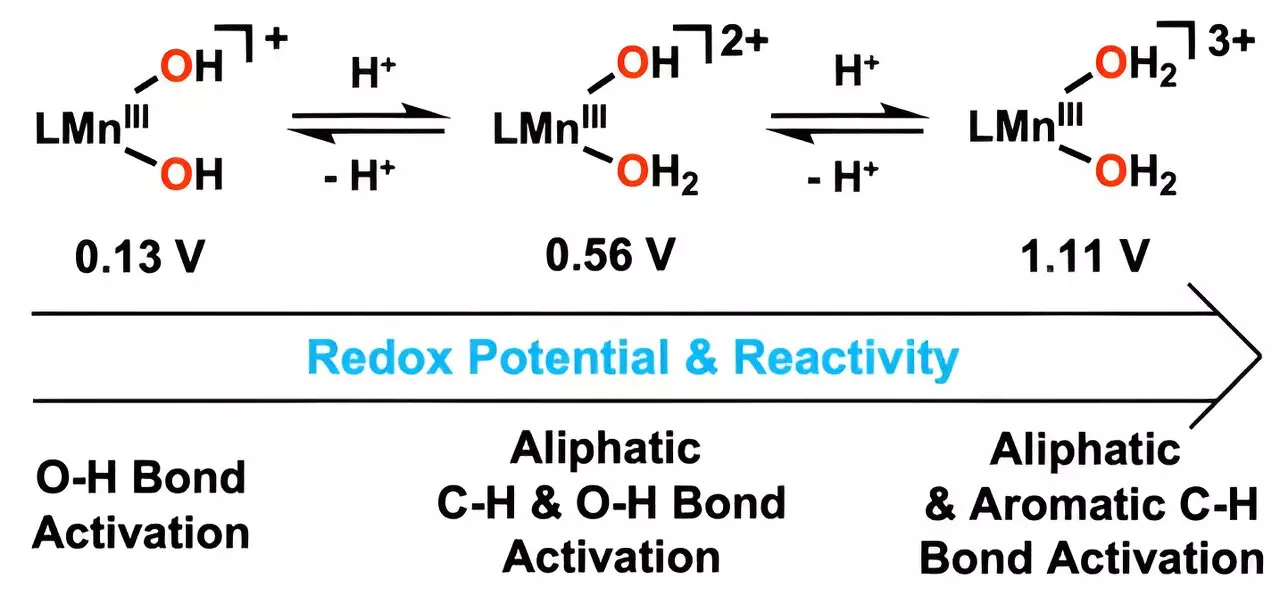

What distinguishes this novel catalyst is its remarkable ability to effectively oxidize hydrocarbons, a vital process for minimizing toxic emissions. The team’s use of manganese as a key component is particularly noteworthy; they have successfully engineered a manganese(III) complex that incorporates two water molecules, enhancing its reactivity with notoriously resilient carbon–hydrogen (C–H) bonds at significantly lower temperatures than conventional methods. By integrating hydrogen ions into the structure, the researchers have ingeniously modified the catalyst’s efficiency, amplifying its capability to initiate oxidation reactions even in challenging conditions.

This advancement is far from trivial. The implications of being able to decompose aromatic hydrocarbons—substances known for their stability and harmful environmental impact—could redefine industrial practices. The smart design behind this catalyst suggests a future where environmental preservation and industrial efficiency can coexist, leading to cleaner air and water.

Implications for Sustainable Technologies

The immediate impact of this research extends beyond academic interest; it has profound implications for industries reliant on the combustion of fossil fuels and other hydrocarbon-based materials. Current pollution control measures often fall short, both in effectiveness and in energy consumption. The ability to utilize this novel catalyst not only promises a more effective means to tackle pollution but also underscores the potential for a reduction in energy input necessary for such processes. Such energy efficiency is a critical component in the pursuit of sustainable technological advancements.

Professor Cho further emphasizes the importance of controlling the reduction potential of manganese in catalyst design, suggesting that this could lead to a new standard in developing industrially relevant catalysts. By achieving better oxidation capabilities without needing energy-intensive processes, the team is laying a foundation for broader applications in waste management and environmental restoration.

Charting a Path Forward

While the research achieved represents a monumental step forward, it is essential to consider how such innovations will translate from laboratory successes to real-world applications. As industries begin to adopt these breakthroughs, a transitional phase will be necessary to navigate the challenges of integrating new technologies into established practices. Nonetheless, the potential to mitigate the environmental footprints of production processes far outweighs these hurdles.

As we stand at the precipice of a new age in environmental chemistry, this novel catalyst is not just a scientific achievement but a beacon of hope for cleaner technologies and healthier ecosystems. The ingenuity displayed by Professor Cho and his team reflects a profound understanding of both nature’s existing solutions and the innovative adaptations that can create even better outcomes. The future is indeed bright for those who dare to leverage the power of chemistry for the benefit of our planet.

Leave a Reply