The construction industry is consistently evolving, with the demand for materials that can withstand extreme stress and provide superior durability growing every year. Among these materials, ultra-high-performance concrete (UHPC) has emerged as a game-changer due to its remarkable mechanical properties. Nevertheless, while UHPC is increasingly used in modern structures, understanding its behavior when confined with fiber-reinforced polymers (FRP) has posed significant challenges. A recent study has sought to address this knowledge gap, introducing a novel stress–strain model that allows for a more nuanced analysis of FRP-confined UHPC.

Conducted by a team of researchers from Huazhong University of Science and Technology and Southern University of Science and Technology, the study led by S.S. Zhang, J.J. Wang, Guan Lin, and X.F. Nie aims to refine existing models that describe the compressive behavior of UHPC when combined with FRP materials. Traditional models have been effective in analyzing normal-strength concrete (NSC) but have fallen short in accurately reflecting the performance of UHPC. Hence, the primary objective of this research was to evaluate the failure mechanisms of UHPC under concentric compression and to develop a more robust analytical model that factors in unique stress-path behaviors observed in UHPC.

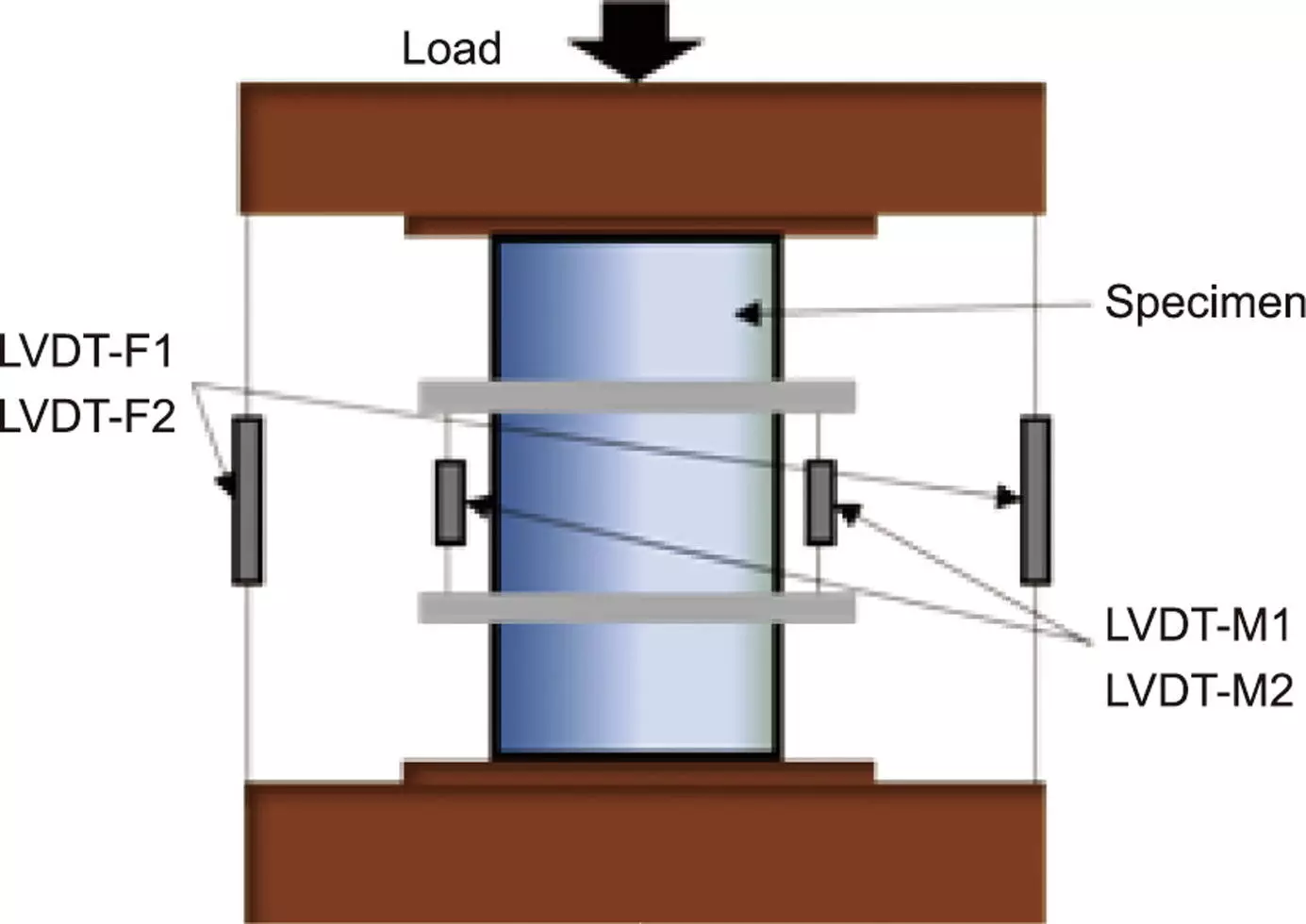

Through a meticulously planned series of experiments, the researchers gathered data on the response of UHPC to concentric compression when confined by FRP. One of the critical insights derived from the experiments was the inadequacy of the stress-path-independency assumption—a principle that works well with NSC but does not translate effectively to the behavior of UHPC.

The study highlights the formation of major diagonal cracks when UHPC is subjected to confinement by FRP, leading to non-uniform lateral expansion. This phenomenon was found to reduce the effective confining pressure that the FRP exerts on the UHPC, showcasing the limitations of traditional stress-path models in this context. Such findings necessitated a reconsideration of how engineers and researchers understand the interactions between UHPC and FRP materials.

In light of their discoveries, the research team developed an innovative analysis-oriented model that integrates stress-path dependency—a significant conceptual shift from prior models. By recalculating confining pressures and introducing a new equation to capture the confining pressure gap, this revised model presents a method for achieving accurate predictions of UHPC behavior under stress.

The validation of this new model was rigorous, leveraging an extensive database of test results to ensure its reliability. This thorough validation process not only confirmed the model’s accuracy but also underscored its potential utility in the field. Moreover, the new model represents a substantial improvement over previous analytical frameworks.

The implications of this research are profound for structural engineering and the construction industry at large. By accurately modeling the behavior of FRP-confined UHPC, engineers can improve the design and safety of structures that utilize high-performance concrete. This advancement opens new avenues for innovative applications, enabling the construction of safer, more efficient buildings and infrastructure.

Furthermore, this study provides an essential tool for researchers and engineers alike, expanding the scope of future investigation into UHPC. Understanding the mechanics involved in UHPC’s performance can prompt transformative changes in concrete technology, catalyzing a new era of sustainable and resilient structures.

The introduction of a stress-path-dependent model marks a significant breakthrough in the comprehension of UHPC’s compressive behavior. Not only does this advancement enhance the structural integrity and longevity of construction projects, but it also paves the way for ongoing research into high-performance concrete applications. As the demand for materials that can withstand the rigors of modern engineering rises, the integration of such innovative approaches will be pivotal in shaping the future landscape of the construction industry. The potential for innovation in concrete technology remains vast, and this research stands as a testament to the ongoing evolution of engineering science.

Leave a Reply