The art of blacksmithing dates back to the dawn of civilization and is intrinsically linked to the strength and utility of metal. Early artisans discovered that deforming metals—through techniques such as hammering or bending—can significantly improve their strength. This process, now recognized as work hardening or strain hardening, has laid the foundation for modern metallurgy, where applications range from the construction of car frames to the manufacturing of overhead power lines. Such techniques not only enhance material properties but are also vital in various industrial processes, underpinning the importance of understanding work hardening comprehensively.

However, up until recently, researchers faced a formidable challenge: observing the real-time dynamics that govern work hardening during deformation. Despite the use of advanced electron microscopes to analyze metal structures before and after deformation, observing the process as it unfolds has remained a scientific endeavor fraught with challenges. The complexity of atomic interactions during work hardening has been poorly understood, primarily because traditional methods provided only a segmented view of the entire process.

A pioneering team from Harvard’s John A. Paulson School of Engineering and Applied Sciences has changed the narrative. Their groundbreaking research, conducted under the auspices of the Harvard Materials Research Science and Engineering Center, has illuminated the intricate mechanisms at play during work hardening. The findings have been published in the prestigious journal Nature, marking a significant step forward in material science.

According to Frans Spaepen, a leading figure in the study and a professor of Applied Physics at SEAS, the research not only enhances the foundational knowledge of work hardening but also has practical implications for developing better predictive models for industrial applications. “Understanding the underlying laws that govern work hardening will make large-scale computer simulations more effective,” he stated, underscoring the vital link between basic research and industrial application.

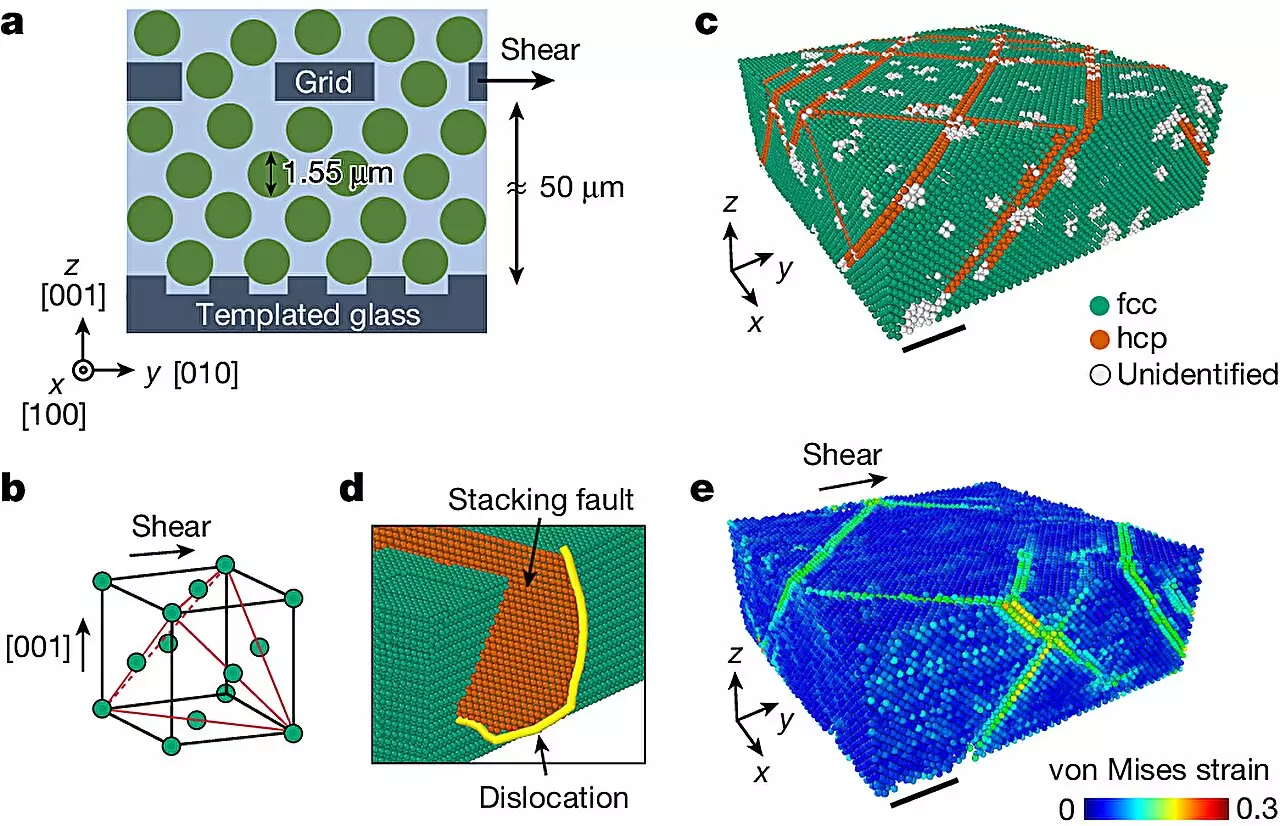

To unravel the complexities of work hardening, the researchers utilized colloidal crystals—structures that are vastly larger than atoms yet share similar properties. These crystals are composed of particles around 10,000 times larger than typical atoms and can spontaneously form intricate crystal arrangements when subjected to high concentrations. Because colloidal crystals undergo analogous phase transitions and exhibit similar defect features, they serve as excellent proxies for studying atomic behaviors.

A unique aspect of this research revolves around the unexpectedly high level of work hardening observed in these colloidal systems. The materials are significantly softer—up to 100,000 times softer than Jell-O. Yet, intriguingly, when strain was applied to these structures, the researchers documented a profound work hardening effect that surpasses that seen in conventional metals like copper and aluminum. This revelation caught the research team by surprise as the interactions among particles appeared too simplistic compared to those found in traditional metals.

The research elucidated that the work hardening in colloidal crystals occurs primarily due to the interactions and entanglement of dislocation defects within the particle structures. This understanding points to a universal mechanism governing not only colloidal crystals but also traditional materials, thereby broadening the implications of the findings.

Seongsoo Kim, a graduate student contributing to the research, remarked on the unexpected outcomes, stating, “The pronounced work hardening we observed goes against conventional wisdom regarding the simplicity of soft materials.” The discovery that these colloidal crystals can achieve greater strength than many metals through work hardening highlights a paradigm shift in how material strength is considered.

This research not only enriches the scientific understanding of material properties but also opens new avenues for material design and applications. David A. Weitz, co-author and a professor at Harvard, emphasized that even understated materials like colloidal crystals can exhibit remarkable strength through work hardening. The insights gleaned from this study demonstrate that fundamental interactions at the micro-scale can yield significant macro-scale improvements, a revelation that could influence future material innovations.

The Harvard SEAS team has made significant strides in clarifying the real-time processes of work hardening, likely affecting how engineers and designers approach materials across various sectors. As they continue to unravel the complexities of material interaction and strength, the route is paved for advanced applications promising to enhance the efficiency and efficacy of numerous industries.

Leave a Reply