In a world where technology is rapidly advancing, the demand for rare earth elements (REEs) like dysprosium and neodymium is on the rise. These metals have niche uses in modern electronics and are classified as “critical minerals” by the U.S. Department of Energy. However, due to their scarcity and similarities in chemical properties, separating these elements from one another has been a challenging task.

Traditionally, liquid-liquid extraction has been the industry standard for isolating REEs. This process involves using organic solvents and chelators to bind to the elements and separate them based on size. While effective to some extent, liquid-liquid extraction is inefficient and generates a significant amount of chemical waste.

A Breakthrough in Metal Processing Technology

A recent study led by chemistry professor Justin Wilson and postdoctoral researcher Yangyang Gao at UC Santa Barbara has introduced a groundbreaking technique for purifying certain REEs at room temperature. This new method eliminates the need for toxic organic solvents and relies on optimized chelators to separate elements more efficiently.

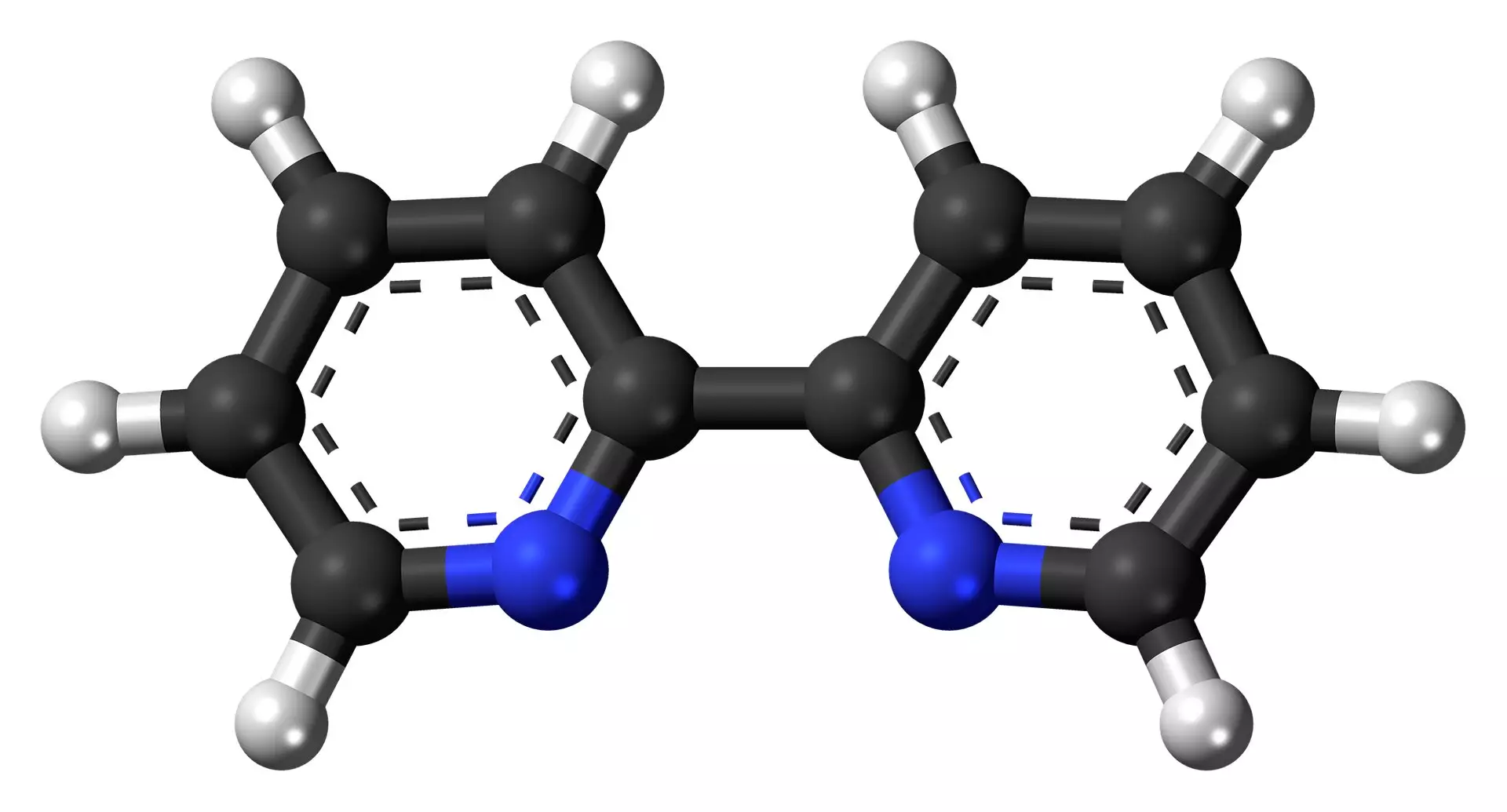

In their research, Wilson and his team developed a chelator called G-macropa, which binds to specific REEs based on their size. By adding sodium bicarbonate to the solution, they were able to precipitate out dysprosium as a carbonate salt, leaving neodymium behind. This innovative approach resulted in over 800 times concentration of dysprosium compared to traditional liquid-liquid extraction methods.

The Significance of the Study

The implications of this new metal processing technology are far-reaching. Not only does it provide a safer and more efficient way to extract REEs from mining operations and electronic waste, but it also has the potential to revolutionize the supply chain for these valuable metals. By reducing the reliance on foreign sources, particularly China, the United States could open up domestic supplies of REEs and boost its national security and economy.

Moving forward, Wilson and his team are focused on refining their technique to work with other rare earth elements and higher concentrations typical of industrial sources. They are also exploring the development of more cost-effective chelators to scale up the process. The success of this research lays the groundwork for further advancements in metal processing technology and recycling practices.

The breakthrough in metal processing technology introduced by Wilson and his team represents a significant step forward in the extraction and purification of rare earth elements. With the demand for these metals expected to increase in the future, innovative approaches like this will play a crucial role in meeting the needs of the growing tech industry while also addressing environmental and sustainability concerns.

Leave a Reply