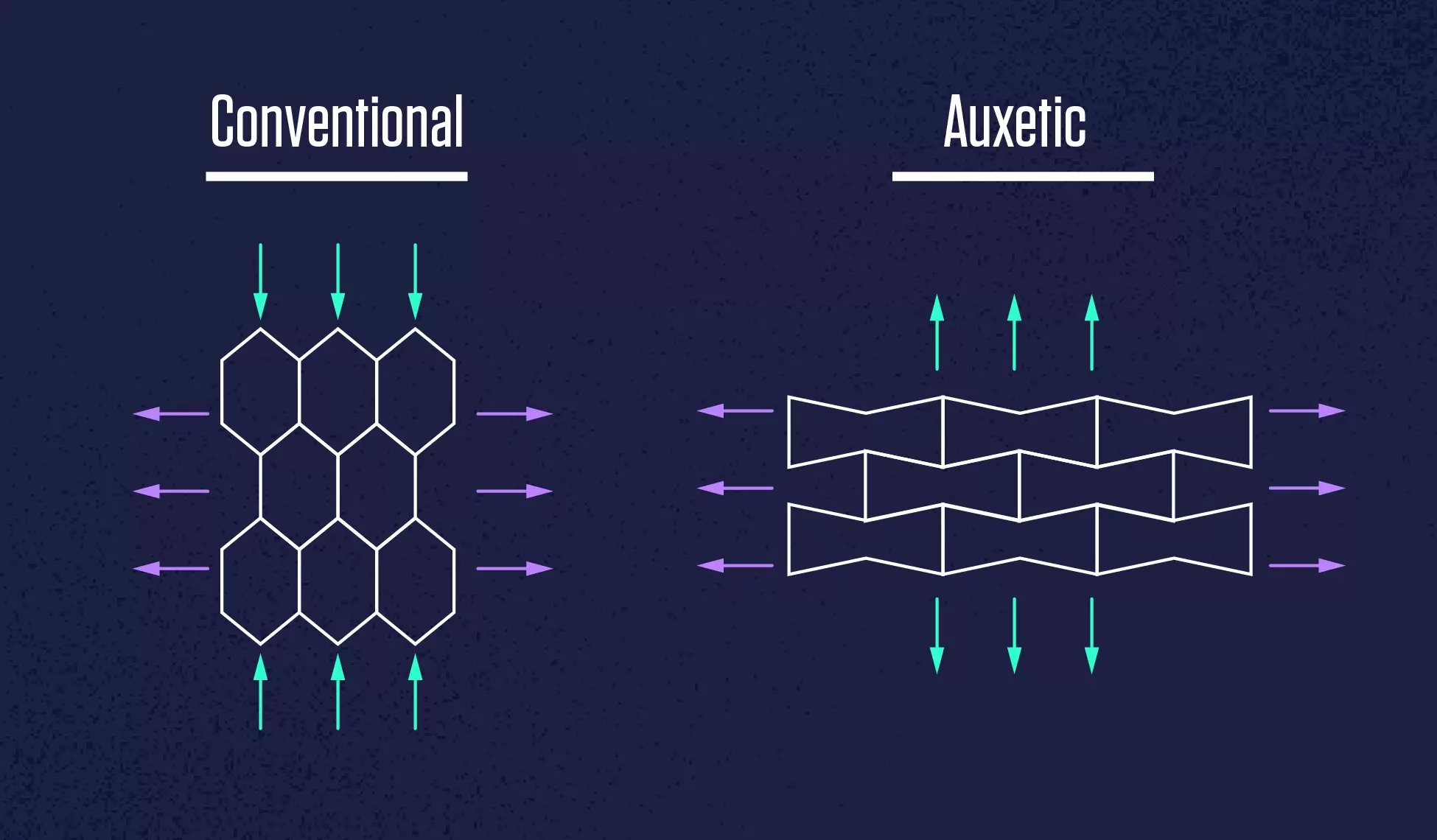

Auxetic materials are a marvel of engineering, defying common sense with their unique properties. When stretched, these materials become wider and fatter, rather than narrower and thinner like conventional materials. This exceptional characteristic opens up a wide range of applications, from sneaker insoles to bomb-resistant buildings.

The Challenge of Bringing Auxetic Products to Market

Despite their immense potential, auxetic products have been slow to enter the market. The development process for these materials has been challenging, requiring precise three-dimensional design to optimize their mechanical properties. However, researchers at the National Institute of Standards and Technology (NIST) and the University of Chicago have made a breakthrough in this area.

In a recent study published in npj Computational Materials, researchers unveiled a new tool that simplifies the design of materials with auxetic properties. This algorithmic tool allows for the precise optimization of auxetic materials, enabling designers to tailor their mechanical properties to specific needs. This advancement signals a significant leap forward in the field of auxetics.

The behavior of elastic materials, including auxetics, is characterized by Poisson’s ratio. Unlike conventional materials with a positive Poisson’s ratio, which expand in all directions when stretched, auxetics have a negative Poisson’s ratio. This unique property allows auxetic materials to contract laterally when stretched, offering enhanced resistance to impacts and pressures.

Auxetic materials hold promise in a wide array of applications, ranging from building construction to athletic footwear. In buildings and automobiles, auxetics can provide superior protection from explosions and collisions. In sneaker insoles, auxetic gels or rubber foams offer enhanced cushioning for the foot upon impact with the ground, while in clothing, auxetic fabrics distribute pressure more evenly across the body, reducing strain on joints and muscles.

The innovative design tool developed by NIST and University of Chicago researchers represents a significant step forward in the field of auxetics. By allowing designers to fine-tune Poisson’s ratio and optimize the structure of auxetic materials, this algorithm opens up new possibilities for creating materials with unprecedented mechanical properties. With the potential to revolutionize various industries, auxetic materials are poised to become more prevalent in our everyday lives.

The journey of auxetic materials from the laboratory to practical applications is marked by innovation and collaboration between theory, experimentation, and computation. The patented algorithm developed by researchers promises to accelerate the adoption of auxetic materials across industries, paving the way for a future where these extraordinary materials are ubiquitous in our daily lives. As we continue to push the boundaries of material science, the possibilities offered by auxetic materials are only beginning to unfold.

Leave a Reply