Green hydrogen stands at the forefront of a revolutionary shift in energy production and storage, heralding a future free from the carbon footprint that has long plagued fossil fuels. As the global community rallies around the ambitious objective of net-zero carbon emissions, particularly championed by the U.S. Department of Energy, the need for efficient and sustainable sources of energy has never been more pressing. Among these emerging solutions, green hydrogen shines not only as an eco-friendly alternative but also as a fundamental component in the broader energy storage infrastructure, offering a clean fuel source derived from the electrolysis of water.

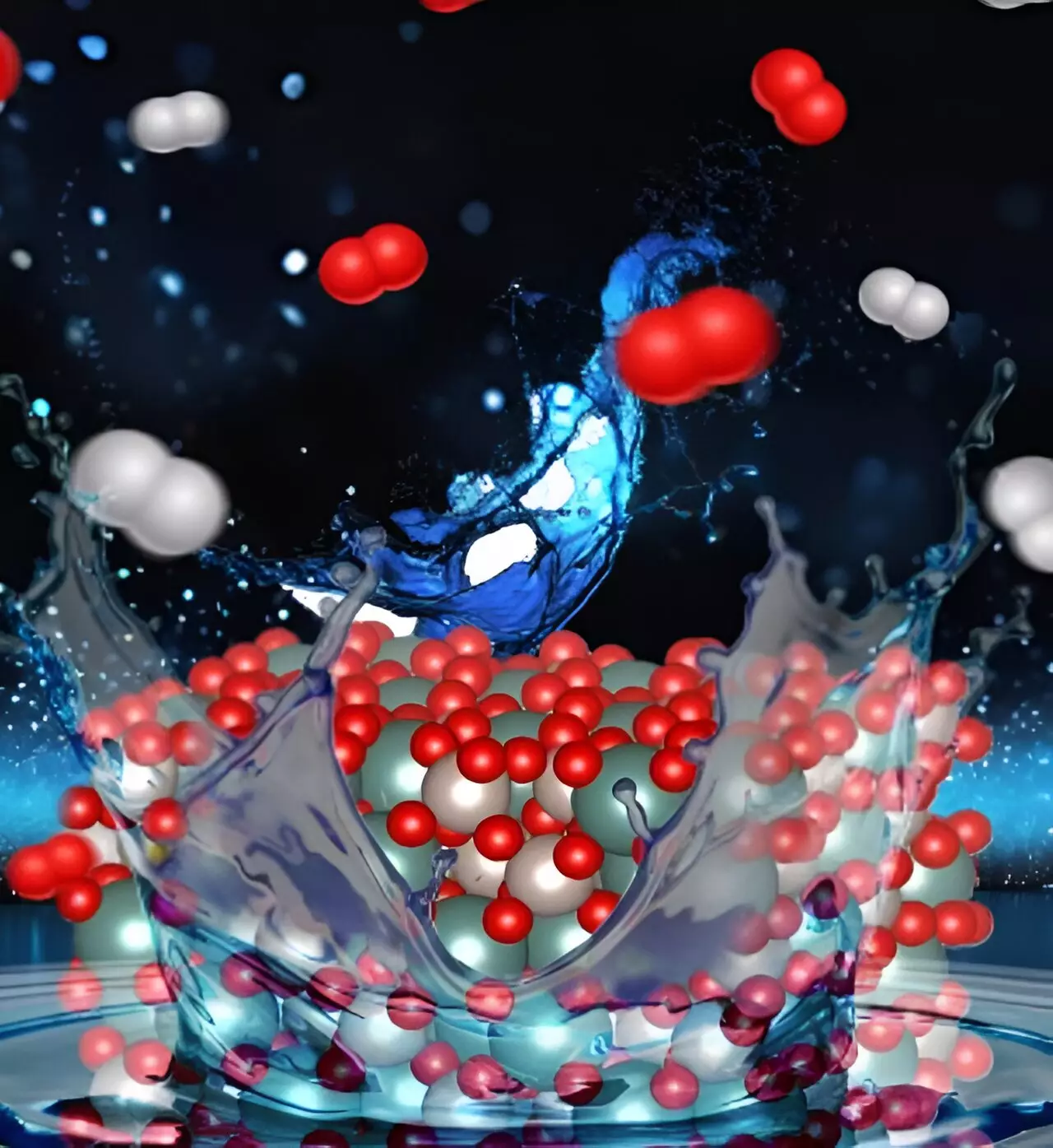

The process of producing clean hydrogen through electrolysis involves splitting water molecules—H2O—into hydrogen and oxygen gases using electrical energy. While renewable energy sources like solar and wind power fuel this transformation, challenges within the electrolysis process itself continue to hinder advancements toward scalable green hydrogen production. The need to optimize electrochemical reactions has led researchers on a quest for innovative strategies to enhance the efficiency of hydrogen generation.

Revolutionary Defect Engineering Techniques

Recent breakthroughs in defect engineering have illuminated a pathway to solving some of the long-standing inefficiencies in hydrogen production technology. A dynamic team of researchers, led by Professor Hong Yang from the field of chemical and biomolecular engineering, has made significant strides in utilizing defect engineering to enhance catalytic efficiency significantly. Their intricate studies, documented in the Journal of the American Chemical Society, showcase the transformative potential of this relatively under-explored domain within electrocatalysis.

At first glance, defect engineering—a method typically associated with semiconductor technology—may seem an unlikely protagonist in the landscape of electrocatalysts. Yet, the principle underlying this strategy is profound: by intentionally introducing ‘defects’ or irregular atoms into a material, the properties of that material can be tailored for enhanced performance. In the case of this research, the base material used for the electrocatalyst is a ruthenium complex oxide with a distinctive pyrochlore structure, where partial substitutions of ruthenium with yttrium dramatically influenced the electrocatalytic activity toward oxygen evolution reactions.

Optimizing Catalytic Reaction Rates

A notable hurdle in traditional electrolysis is the imbalance in reaction rates for hydrogen and oxygen gas production. While hydrogen can be produced at a swifter rate, the slow generation of oxygen gas has long constrained overall production capacity, limiting the current flow and efficiency of electrolyzers. However, the innovation introduced by the researchers promises to address these challenges head-on. By leveraging defect engineering techniques, they successfully redesigned the electronic structure of ruthenium to create a more effective catalyst capable of expediting oxygen gas production.

The introduction of yttrium into the ruthenium lattice is not a random act; the meticulous balance of ‘imperfections’ is crucial to realizing performance benefits. Yang notes that just as impurities enhance the efficacy of silicon chips, the deliberate modification of ruthenium’s electronic configuration by way of defect engineering has led to noteworthy advancements in catalytic response. The insight derived from this approach highlights a counterintuitive reality: enhancing efficiency does not stem merely from increasing the availability of reactants but rather from enlightening the electronic interactions between them.

Experimental Insights and Collaborative Prowess

The depth of this research underscores the importance of a multidisciplinary approach in tackling complex scientific challenges. The collaboration between experts in various fields allowed the team to surmount technical obstacles in characterizing their innovative electrocatalysts. Through rigorous experimentation involving thermogravimetric analysis, they unveiled the connection between defects in the catalyst and its performance in generating oxygen gas.

Bidipta Ghosh, a graduate student and lead author of the research, articulates a critical finding: the oxidation state of the material, altered by yttrium introduction, played a pivotal role in enhancing reaction vigor, while the concentration of oxygen vacancies remained constant. This delicate balance elucidates the nuanced dynamics at play in electrocatalytic performance—teaching us that small variations in material composition can lead to significant shifts in behavior.

The Path Ahead: Implications for Sustainable Energy

The research team’s discoveries present not just an advancement in academic knowledge, but also bear practical implications for the industrial-scale production of green hydrogen. Their innovative approach to defect engineering could prove essential as industries seek to accelerate the transition toward sustainable energy solutions. As we stand on the brink of a potential green hydrogen economy, this work exemplifies how scientific ingenuity can address the pressing environmental challenges ahead.

By recognizing and harnessing the power of imperfections within materials, researchers are paving the way for breakthroughs that could redefine energy landscapes. The drive for sustainable energy sources, coupled with advancements in catalytic technology, highlights a promising future where clean, low-cost hydrogen fuels industries and households alike—an evolution that could significantly reduce our collective carbon footprint. The innovation illustrated in this study is merely a glimpse of the remarkable journey ahead in catalyzing a greener and more sustainable future.

Leave a Reply