Understanding how microstructural features relate to the properties of materials is a critical task in material science, especially for the advancement of next-generation structural and functional materials. The complexity of this relationship poses significant challenges. Numerous factors, including the physical arrangement of molecules and their interactions, play pivotal roles in determining how a material behaves under various conditions. Therefore, establishing a clear link between the microscopic structure of a material and its macroscopic properties is a pressing need in the field.

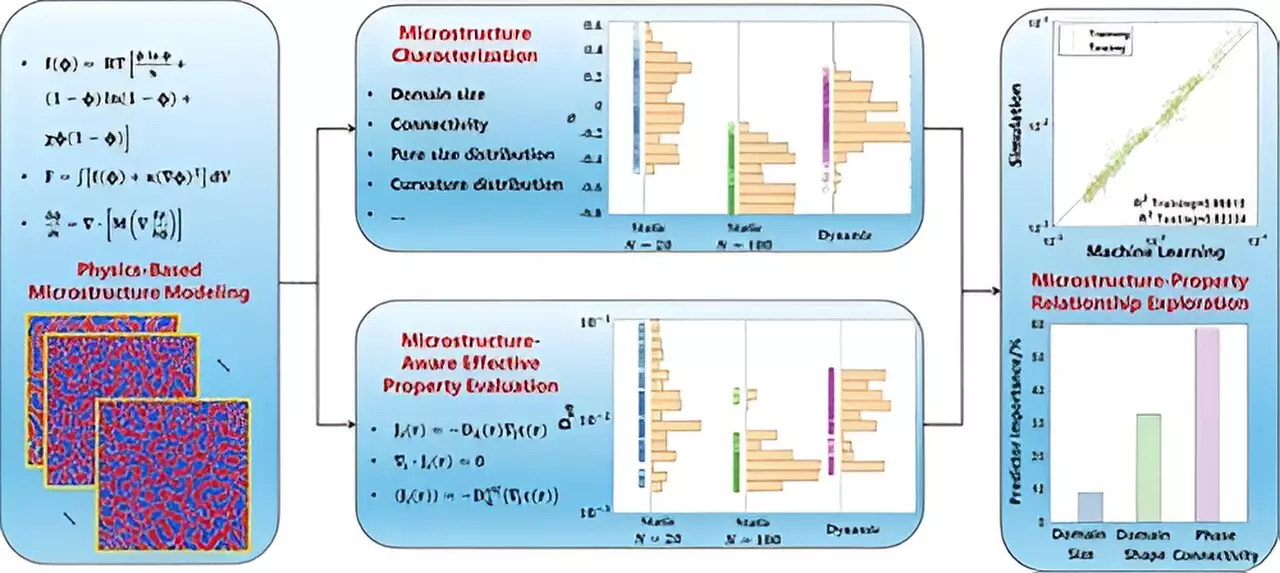

In an endeavor to tackle the intricacies of these relationships, scientists at Lawrence Livermore National Laboratory (LLNL) have introduced a groundbreaking computational framework. This system integrates various components including physics-based microstructure modeling, microstructure feature extraction, effective property evaluation, and machine learning analysis tools. According to Longsheng Feng, a leading researcher in this project, the framework not only addresses existing complexities but also streamlines the intricate processes involved in analyzing microstructural properties of materials.

The innovative framework was applied to polymer-based porous materials, serving as a focal point for understanding how polymerization dynamics influence microstructural characteristics. Key aspects examined include domain size and pore size distribution, both of which significantly affect the materials’ transport properties. By elucidating these connections, the researchers aim to provide insights that can influence the development of more efficient and tailored materials.

Aiming for Tailored Material Properties

The overarching goal of this research is to create a systematic approach for discerning which specific microstructural features impact different material properties and the mechanisms involved. Tae Wook Heo, a co-author of the study, emphasizes the importance of understanding not just how microstructures form, but also how their configurations translate into functional outcomes. This knowledge is vital for creating materials with enhanced performance tailored for specific applications.

The findings from this research have far-reaching implications. Juergen Biener, another co-author, points out that a thorough understanding of microstructure-property relationships can inform processing methods to achieve desired characteristics in polymer porous materials. Such developments could open the door for more effective applications, including advanced membranes necessary for filtration, separation processes, and other technological innovations.

The LLNL team’s pioneering work represents a significant step forward in material science research, especially for polymer-based porous materials. By integrating advanced computational modeling with machine learning and detailed microstructural analysis, they have created a tool that enhances our understanding of material properties. This could ultimately lead to the design of more efficient materials, tailored for a diverse array of practical applications. The future of material science looks promising as researchers continue to unravel complex relationships that dictate material behavior at micro and macro scales.

Leave a Reply